Brine mixer

Air dried non-fried instant noodle production line

Classification:

Product Introduction

Product Details

Product Introduction and Features

HFP800 Type Hot Air Drying Instant Noodle Production Line

Main parameters of production line

Production capacity:420pcs/min,80g/pc, Square noodle cake

roller width :800mm

Roller number: 9 groups

Steaming operation mode:3-layers horizontal reciprocating type

Steaming time:1650s

Drying time: about 30min

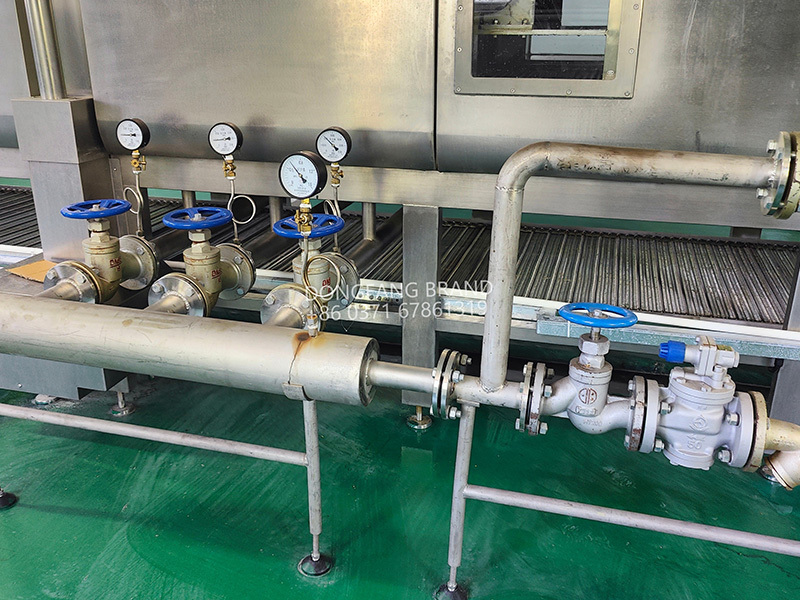

Heating medium: steam

Noodle oil content:≦18%

Steam consumption: about 3000kg/h

Steam pressure:8kg

Installed capacity:About 182KW

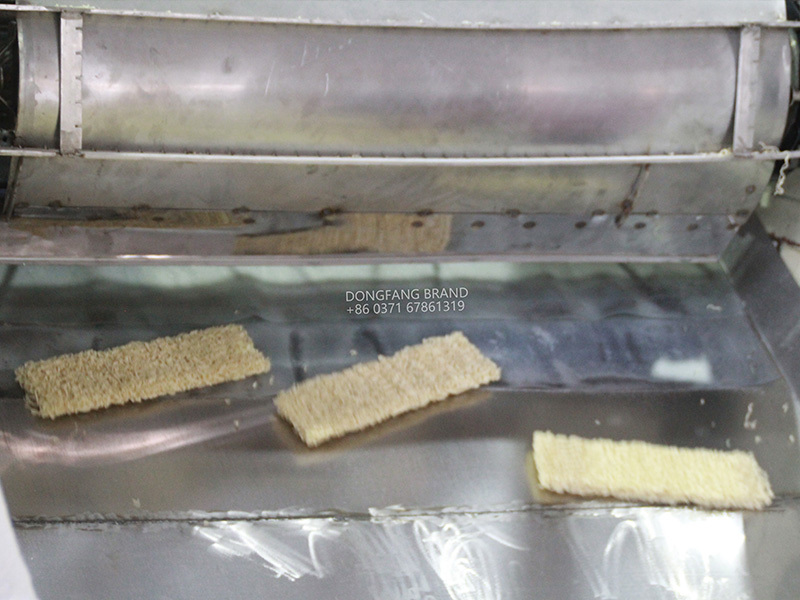

The hot-air drying instant noodle production line produced by our company is equipped with a hot-air dryer to dry the noodle blocks. It is an automatic non-fried instant noodle production equipment. The noodle block produced is square, and the dryer can be divided into three-layer dryer, five-layer dryer or seven-layer dryer. Through chain transmission, the noodle block in the noodle box is dried in the process of running in the dryer, and the water is discharged out of workshop.

The hot air dryer occupies a small area and does not require manual operation. The well-designed air duct system ensures that the wind go through the noodle blocks. The dryer runs smoothly and reliably, and the noodle blocks does fall off. After drying, it is easy to take off the box. The heat energy is recycled and heated step by step. After fully use, heat is discharged outdoors with the damp steam. The noodle blocks produced have high water content, beautiful appearance and good taste.

Non-fried instant noodles are currently a very popular product. They can be sold directly through the Internet, with fast delivery, large profits, healthy and nutritious products, and are the preferred products of consumers.

Features of Instant Noodle Production Line

1. The noodle blocks' shape is neat, the ripples and the color are uniform.

2. Fast production, large capacity, Steam saving, and low oil consumption.

3. Finished products meet food safety requirements. The production process conforms to safety operation standard

4. Good stability, low failure rate, simple operation and beautiful appearance.

5. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

6. The parts or equipment of every link of the equipment in the entire production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

7. All transmission parts have outer shields to ensure safe operation without accidents.

Our company has a complete the system of QoS(Quality of Service) guarantee including product development, manufacturing, pre-sales and after-sales . While manufacturing high-quality instant noodle production lines for customers, we also provide users with comprehensive services.

Pre-sale: Plant area planning; drawing production line layout; Selection of supporting equipment, purchasing; Product positioning analysis.

After-sales: Send installers to the site to install and debug the production line to produce qualified noodles; Training users how to operate the production line, maintenance, and production management; Free lifetime telephone consultation.

New Type Non-fried Round Instant Noodles (Cup Noodles) Production Line

The new automatic non-fried round instant noodle (cup noodle) production line manufactured by our company has the characteristics of high degree of automation, stable operation, large output, energy saving, low production cost, neat and beautiful noodle shape and so on. The produced noodle is also popular with consumers because of its health, nutrition and delicious taste.

The “non-frying” means that the noodles are dried by hot air. The fan equipped with the dryer has strong wind power, and the wind power is 5 times that of ordinary fans. The noodle blocks can be dried quickly in 30 minutes.

The hanging basket dryer is a new drying transmission mode developed by our company, which can allow the hot air to blow evenly on the surface of the noodle blocks. The wind and heat received by each noodle block are the same, and the water is discharged during the operation of the noodle block, to ensure the quality and taste of the noodles are consistent.

Features of Instant Noodle Production Line

1. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

2. The parts or equipment of every link of the equipment in the entire production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

3. All transmission parts have outer shields to ensure safe operation without accidents.

4. The noodle blocks' shape is neat, the ripples and the color are uniform.

Our company has a complete the system of QoS(Quality of Service) guarantee including product development, manufacturing, pre-sales and after-sales . While manufacturing high-quality instant noodle production lines for customers, we also provide users with comprehensive services.

Process technology parameter table, please select the product you are interested in based on production capacity or model

| MODEL | CAPACITY | POWER | STEAM CONSUMPTION | WORKSHOP DIMENTION | WORKERS | |

| HFP300 | 165pc/h | 70KW | 1400~1600KG/H | 80×7x6 | 6 | |

| HFP400 | 200pc/h | 85KW | 1600~1800KG/H | 90×7x6 | 7 | |

| HFP500 | 275pc/h | 110KW | 1800~2000KG/H | 100x7x6 | 8 | |

| HFP600 | 330pc/h | 135KW | 2500~2600KG/H | 105x8x6 | 8 | |

| HFP700 | 385pc/h | 166KW | 2600~2800KG/H | 110x6x4.5 | 10 | |

| HFP800 | 420pc/h | 180KW | 3000~3000KG/H | 120x7x4.5 | 12 | |

| HFP1000 | 550pc/h | 230KW | 3500~3700KG/H | 130x7x4.5 | 12 | |

| Note: The number of workers is the number of people per shift, excluding packaging staff.(WORKERS:NOTINCLUDING PACKAGING WORKERS) | 16 | |||||

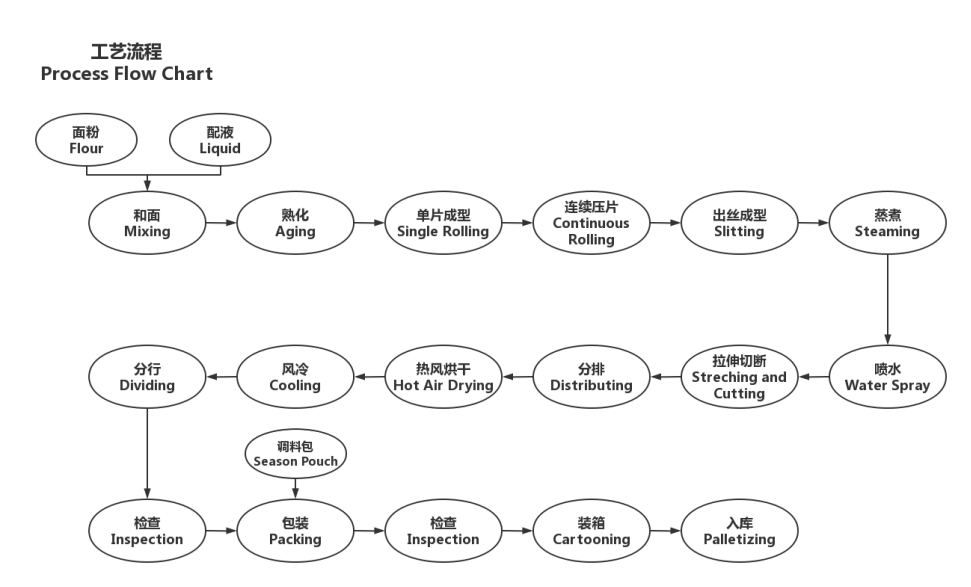

Production line process flow

Main unit machine pictures

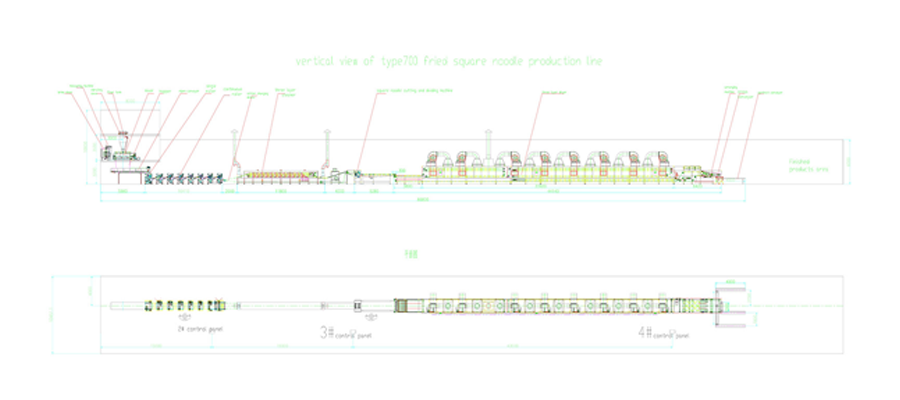

Production line workshop layout

Production line video

Key words:

Air dried non-fried instant noodle production line

Fried Instant noodle production line

Layout

File size: 710.9KB

Upload Date:2025-05-19

Please leave us a message

Feel free to leave your contact information for more information