Dough mixer

BFP300 Fried Instant Noodle Production Line

Classification:

Product Introduction

Product Details

INTRODUCTION TO TYPE300 FRIED INSTANT NOODLE PRODUCTION LINE

This is a small, low capacity automated fried instant noodle production line, suitable for users with low investment budgets, small workshop areas, and first-time processing of instant noodles, if the product is in high demand after being put into the market, they can choose a production line with larger production capacity, it’s technical features, market positioning, price advantage, and customer positioning are as follows:

A: Technical features

- Low capacity design: The production capacity range is usually 5000-10000 packages per hour, suitable for small batch and multi variety production.

2. High flexibility: can quickly switch between different recipes (such as different flavors and shapes of noodle cakes). Like square or round noodle cakes.

3. Moderate degree of automation: Processes of fried instant noodle production line such as kneading, rolling, cutting, steaming, frying, cooling, conveying, and packaging are automated to reduce manual intervention.

4. Small space requirement: The length of the fried instant noodle production line is usually 55 meters, suitable for small factories or leased spaces.

B: Market positioning

1. Target market: Small and medium-sized cities in Southeast Asia, Africa, Latin America, and other regions with rapidly growing demand for convenience foods but high investment barriers for large-scale production lines.

2. Differentiation: Avoid competition with giants such as Kangshifu and Uni President, and focus on small batch, customized, and localized products.

C: Price advantage

1. Low investment cost: The overall investment cost of small fried instant noodle production line is low, and the price can meet the budget of user investment.

2 . The demand for factory space is small, resulting in a significant reduction in rent or construction costs.

3. Labor cost: Each shift only requires 3-5 people, suitable for areas with abundant labor but lower salaries.

Energy consumption optimization: Low capacity design avoids energy waste and reduces unit energy consumption costs.

3. Fast return cycle: Under stable orders, it is usually pays back within one year (depending on product pricing and sales volume).

D: Customer positioning

1. Start up companies/small and medium-sized food factories: companies with limited funds but hoping to enter the convenience food industry.

2. Small and medium-sized customers: Distributors or agents in Southeast Asia, Africa, and other regions who purchase equipment for localized production.

Summarize

The core value of a small-scale, low capacity automated fried instant noodle production line lies in its low investment, fast updates, and low risk, making it an ideal choice for entering the instant noodle market for the first time.

Features of fried Instant Noodle Production Line

1. The noodle cake' shape is neat, the ripples and the color are uniform.

2. Finished products meet food safety requirements. The production process conforms to safety operation standard

3. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

4. The parts or equipment of every link of the equipment in the entire production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

5. All transmission parts have outer shields to ensure safe operation without accidents.

Process technology parameter table, please select the product you are interested in based on production capacity or model

| Model | Production Capacity (70g/piece) | Installed Capacity | Steam Consumption | Workshop Requirements L×W×H(METER) |

| Model 1000(type) | 600(pcs/min) | 170KW | 4500kg/h | 130×8×6 |

| Model 900(type) | 540(pcs/min) | 170KW | 4000kg/h | 120×8×6 |

| Model 800(type) | 480(pcs/min) | 140KW | 3600kg/h | 110×6×6 |

| Model 700(type) | 420(pcs/min) | 130KW | 3100kg/h | 100×6×6 |

| Model 600(type) | 360(pcs/min) | 110KW | 2600kg/h | 100×6×6 |

| Model 500(type) | 300(pcs/min) | 80KW | 2200kg/h | 90×6×6 |

| Model 400(type) | 240(pcs/min) | 70KW | 1800kg/h | 90×6×6 |

| Model 300(type) | 126(pcs/min) | 60KW | 900kg/h | 85×6×6 |

| Model 200(type) | 84(pcs/min) | 50KW | 700kg/h | 80×6×6 |

Production line process flow

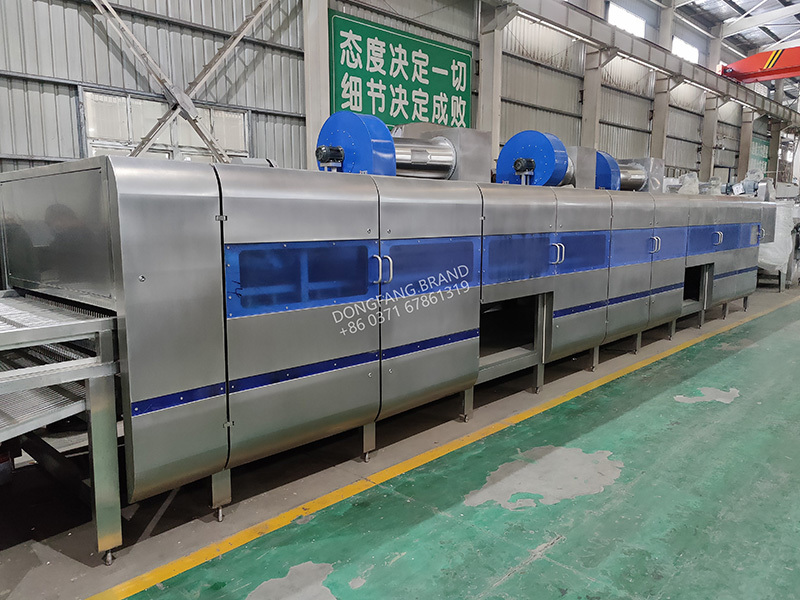

Main unit machine pictures

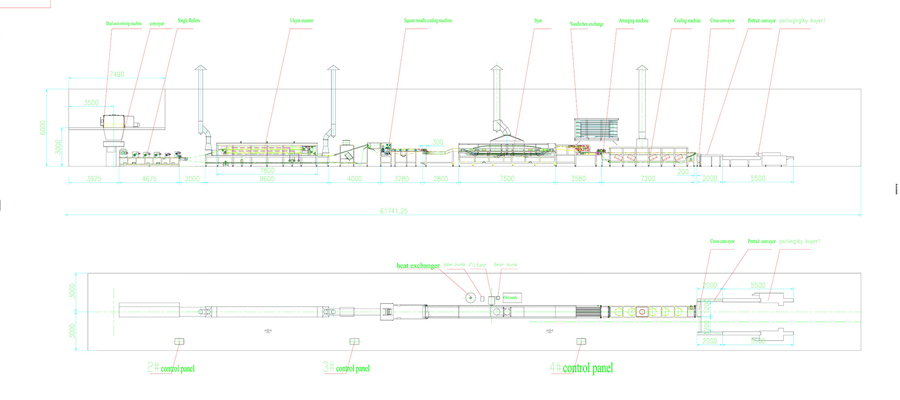

Production line workshop layout

Production line video

Key words:

BFP300 Fried Instant Noodle Production Line

Fried Instant noodle production line

Layout

File size: 338.9KB

Upload Date:2025-05-19

Please leave us a message

Feel free to leave your contact information for more information