Continuous mixer

stick noodle making machine

Classification:

Product Introduction

Product Details

Product Introduction and Features

Automatic Stick Noodle Production Line

Our company founded in 1975, is the most popular manufacturer of dried noodles in China. The top 10 noodle manufacturers in China are all our partners.

The stick noodle production line's transmission operation mode of the drying room produced by our company is divided into straight chain and turning chain. It is a kind of low-temperature drying technology, and the drying time is about 4.5 hours.

The main features of the straight chain stick noodle production line are: reasonable design, stable performance, compact structure, convenient operation, high degree of automation, small covering, easy control of temperature and humidity, and capacity from 3 tons to 20 tons per 8 hours.

The main features of the turning chain stick noodle production line are: the equipment layout can be designed according to the customer's existing workshop. With high flexibility, the drying room can be filled by turning. The requirements for the length of the workshop are not strict, the temperature and humidity can be automatically controlled, and the operation is simple. Large capacity from 3 tons to 30 tons per 8 hours.

High degree of automation: Flour supply by air feeding; Equipped with continuous dough mixer, the dough after ripening is directly sent to the roller. After continuous rolling, the dough sheet is automatically slitted and put on the rod to enter the drying room. The noodles are continuously dried in the drying room for 4.5 hours, the dried noodles are sent to the cutting machine to be cut, and then sent to the weighing machine through the conveyor belt for final packaged. The entire process from flour to noodle is completed mechanized, with 2 operators.

The finished product that can be processed: longevity noodles, egg noodles, chow mein, boiled noodles, etc.

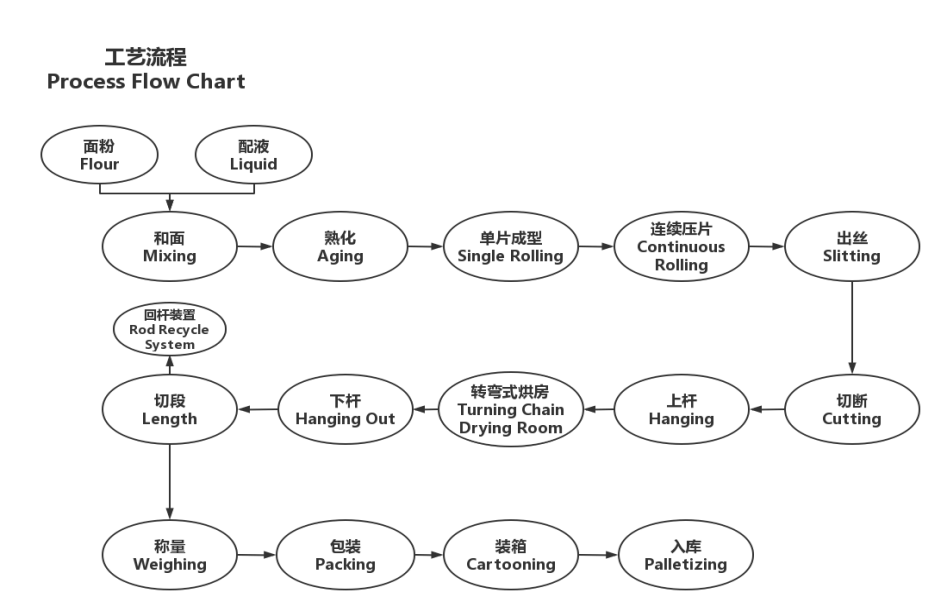

Production line process flow

Process technology parameter table, please select the product you are interested in based on production capacity or model

| Model | Production Capacity | Installed Capacity | Workshop Requirements LxW×H(dryingroom height )DoubleChain Straight Type | Workshop Requirements L×W×H(drying room height) Double Chain TurningType |

| 1500型(type) | 90T/24H | 258KW | 190×10×5.5(3.5)(M) | 120×18×5.5(3.5)(M) |

| 1000型(type) | 55T/24H | 146KW | 100×12×5.5(3.5)(M) | 80×18×5.5(3.5)(M) |

| 850型(type) | 43T/24H | 115KW | 100×11×5.5(3.5)(M) | 80×16×5.5(3.5)(M) |

| 765型(type) | 36T/24H | 110KW | 90×10×5.5(3.5)(M) | 80×15×5.5(3.5)(M) |

| 650型(type) | 30T/24H | 80KW | 75×10×5(3.5)(M) | 80×14×5(3.5)(M) |

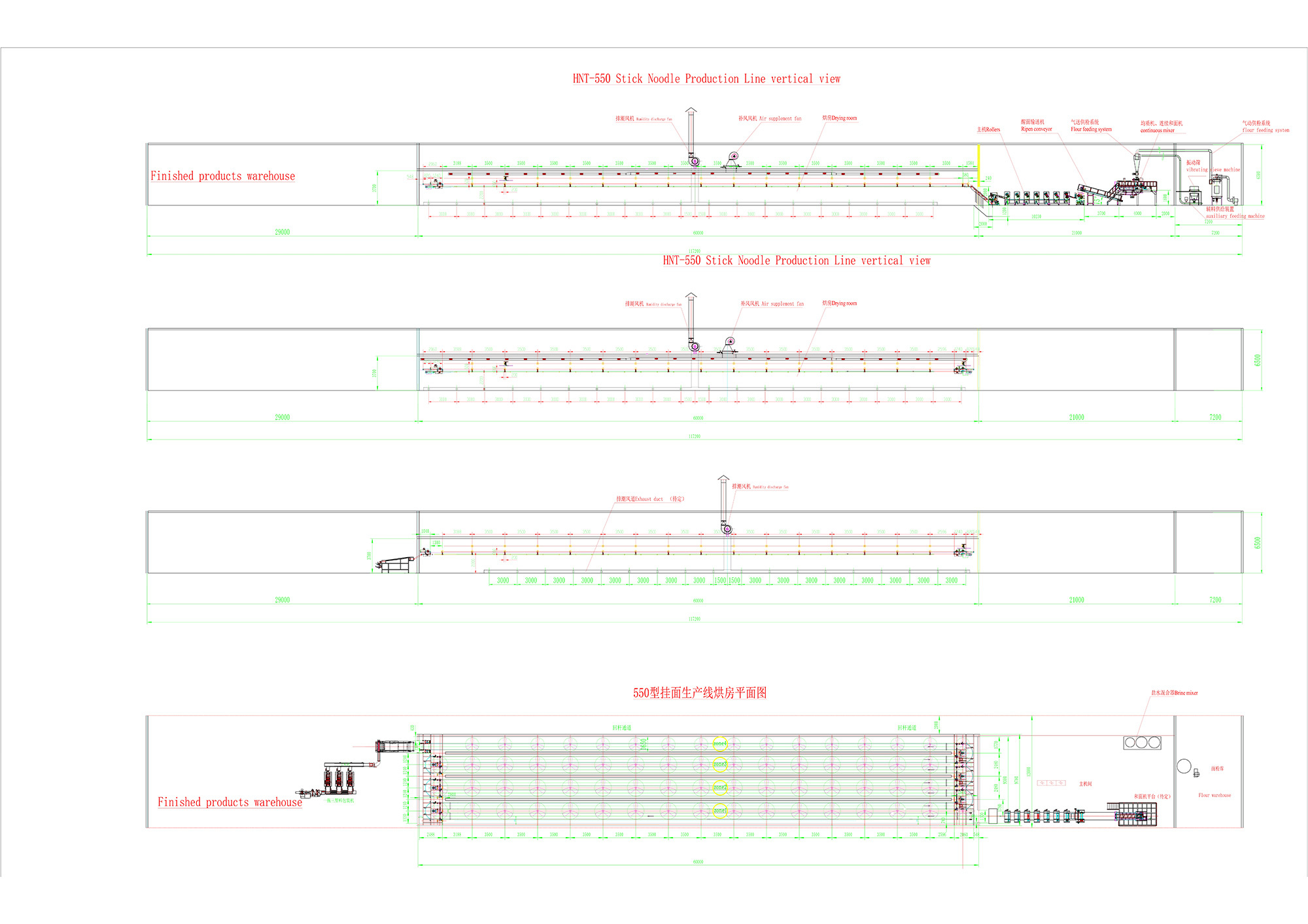

| 550型(type) | 23T/24H | 75KW | 65×9×5(3.5)(M) | 80×13×5(3.5)(M) |

| 450型(type) | 18T/24H | 70KW | 65×8×5(3.5)(M) | 80×11×5(3.5)(M) |

Main unit machine pictures

Production line workshop layout

Production line video

Key words:

stick noodle making machine

Stick noodle production line

Layout

File size: 3.0MB

Upload Date:2025-05-19

Please leave us a message

Feel free to leave your contact information for more information