Mixer

BFP600 Fried Cup Noodle Production Line

Classification:

Product Introduction

Product Details

WFP600 Fried Cup packaging Instant Noodles Production Line

Main parameters of production line

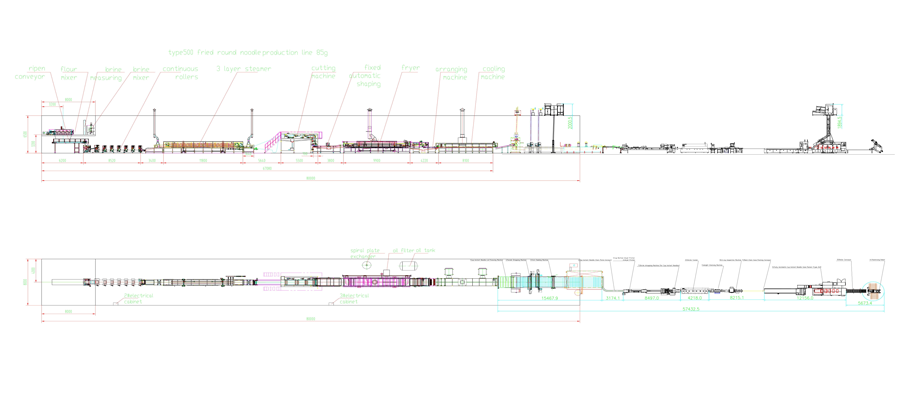

Production capacity:300pcs/min,70g/pc

roller width :600mm

Roller number: 8groups

Steaming operation mode:3-layers horizontal reciprocating type

Steaming time:180s

Frying time: 135s

Heating medium: steam

Noodle oil content:≦18%

Steam consumption: about 2100kg/h

Steam pressure:8kg

Installed capacity:About 130KW

The WFP600 fried cup instant noodle production line is a highly automated and technologically advanced noodle food production equipment, mainly used for producing fried cup instant noodles. The production line has achieved automated operations in all aspects of raw material mixing, kneading, rolling, frying, cooling, and packaging, which not only improves production efficiency but also ensures product quality stability and consistency.

A: Technical advantages

1. Automation control system: Using PLC programming controller and touch screen operation, it can achieve precise control and monitoring of various parameters in the production process, such as the mixing speed of the dough mixer, the rolling speed of the rolling machine, the oil temperature and time of the frying machine, etc., to ensure that the quality of each noodlecake can meet the standards.

2. Advanced frying technology: Equipped with efficient frying equipment, precise oil temperature control, and electric adjustment between 140 ℃ and 160 ℃, the noodlecake can achieve ideal color, taste, and oil content. At the same time, equipped with an oil circulation filtration system, it can effectively remove impurities and odors in the oil, extend the service life of the oil, and reduce production costs.

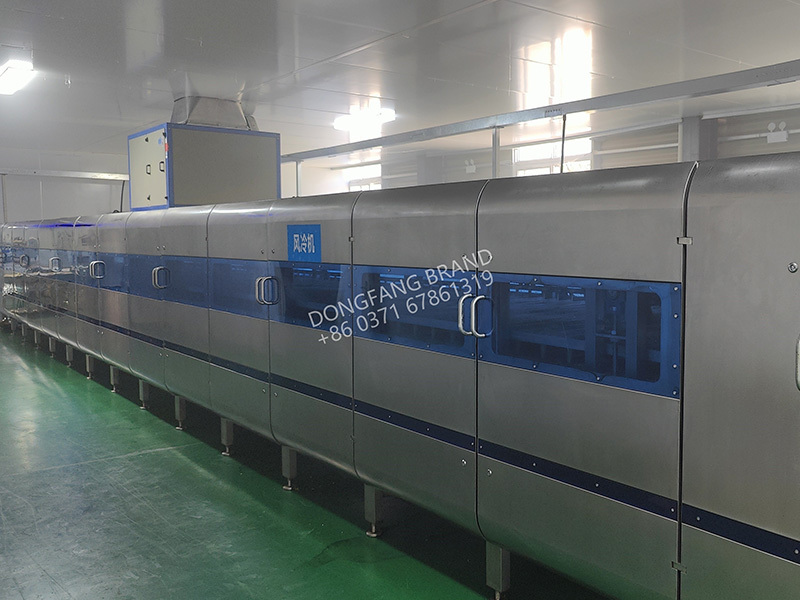

3. Efficient cooling equipment: Using advanced air cooling technology, the fried noodlecake can be quickly cooled to near room temperature, improving packaging efficiency and product quality, while avoiding the noodlecake from becoming soft or sticking at high temperatures, ensuring the appearance and taste of the product.

B: Production capacity and efficiency

The WFP600 fried cup instant noodle production line has a strong production capacity, which can produce 140000pcs of instant noodles in 8 hours. Compared with traditional production lines, the production efficiency has increased by more than 30%. Its high degree of automation eliminates the need for manual intervention during normal production processes, reducing errors and instability caused by manual operations while lowering labor costs.

C: Product quality and taste

The fried cup instant noodles produced by this production line have neat and beautiful noodle shapes, smooth and chewy noodles, short rehydration time, and a taste similar to fresh noodles. The oil content can be adjusted according to customer needs to meet the taste preferences of different consumers, and the shelf life can be as long as 6-12 months.

D: Market demand and prospects

With the acceleration of global urbanization and the pace of life, instant noodles, as a fast and convenient food, have seen a continuous increase in market demand. Especially in regions such as Asia Pacific, Africa, and Latin America, the consumption of instant noodles continues to rise, providing a vast market space for fried cup instant noodle production lines.

The WFP600 fried cup instant noodle production line has broad development prospects in the international market due to its high degree of automation, advanced technology, high production efficiency, and good product quality. For enterprises interested in investing in the field of instant noodle production, choosing the WPF600 fried cup instant noodle production line is undoubtedly a wise decision, which can help the enterprise quickly seize market share and create substantial economic benefits.

Features of Instant Noodle Production Line

1. The noodle cake' shape is neat, the ripples and the color are uniform.

2. Fast production, large capacity, Steam saving, and low oil consumption.

3. Finished products meet food safety requirements. The production process conforms to safety operation standard

4. Good stability, low failure rate, simple operation and beautiful appearance.

5. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

6. The parts or equipment of every link of the equipment in the entire production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

7. All transmission parts have outer shields to ensure safe operation without accidents.

Our company has a complete the system of QoS(Quality of Service) guarantee including product development, manufacturing, pre-sales and after-sales . While manufacturing high-quality instant noodle production lines for customers, we also provide users with comprehensive services.

Pre-sale: Plant area planning; drawing production line layout; Selection of supporting equipment, purchasing; Product positioning analysis.

After-sales: Send installers to the site to install and debug the production line to produce qualified noodles; Training users how to operate the production line, maintenance, and production management; Free lifetime telephone consultation.

Process technology parameter table, please select the product you are interested in based on production capacity or model

| Model | Production Capacity (70g/piece) | Installed Capacity | Steam Consumption | Workshop Requrements L×W×H(METER) |

| Model 1200(type) | 480(pcs/min) | 223KW | 4200kg/h | 140×8×6 |

| Model 1000(type) | 420(pcs/min) | 180KW | 3600kg/h | 130×8×6 |

| Model 900(type) | 360(pcs/min) | 180KW | 3100kg/h | 130×8×6 |

| Model 800(type) | 330(pcs/min) | 150KW | 2800kg/h | 120×8×6 |

| Model 700(type) | 300(pcs/min) | 140KW | 2600kg/h | 120×8×6 |

| Model 600(type) | 300(pcs/min) | 120KW | 2600kg/h | 110×8×6 |

| Model 500(type) | 240(pcs/min) | 90KW | 2000kg/h | 100×8×6 |

| Model 400(type) | 200(pcs/min) | 90KW | 1700kg/h | 85×8×6 |

| Model 300(type) | 126(pcs/min) | 90KW | 1000kg/h | 80×8×6 |

Main unit machine pictures

Production line workshop layout

Production line video

Key words:

BFP600 Fried Cup Noodle Production Line

Layout

File size: 2.2MB

Upload Date:2025-05-19

Please leave us a message

Feel free to leave your contact information for more information