Brine mixer

BFP600 Fried Instant Noodle Production Line

Classification:

Product Introduction

Product Details

Introduction to BFP600 Fried Square Instant Noodle Production Line

Main parameters of Fried Square Instant Noodle Production Line

Production capacity:360pcs/min,70g/pc

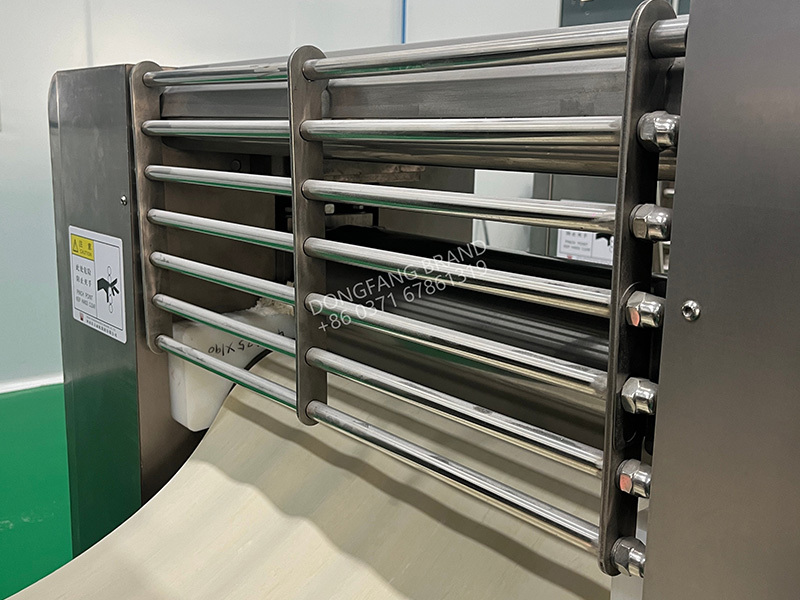

roller width :600mm

Roller number: 8groups

Steaming operation mode:3-layers horizontal reciprocating type

Steaming time:150s

Frying time: 90s

Heating medium: steam

Noodle oil content:≦18%

Steam consumption: about 2300kg/h

Steam pressure:8kg

Installed capacity:About 121KW

BFP600 fried square instant noodle production line, with production capacity of 170,000pcs per 8hours. For fried instant noodle production enterprises that already have a certain market foundation but have not yet reached the level of large-scale enterprises, the medium-sized production capacity of this fried instant production line perfectly meets their needs. It can meet the daily production supply market without worrying about resource waste caused by overcapacity, which helps enterprises steadily expand production and increase market share according to their own development stage. The main characteristics of the production line are described in detail as follows:

A: Advanced technology

The fried instant production line adopts advanced frying technology. For example, using multi-stage frying technology, instant noodles are first pre fried at a lower temperature to allow the noodles to mature and form a certain texture foundation. Then, frying is carried out at a higher temperature to effectively control the penetration of oil, ensuring that the taste of instant noodles is crispy and not easily greasy.

Through an automated control system, it is possible to accurately add raw materials such as flour, water, salt, etc. according to preset proportions, and the mixing speed and time are also optimized. This ensures that the gluten and moisture content of the dough reach their optimal state, providing favorable conditions for subsequent rolling and shaping.

2. The key equipment on the fried instant production line, such as frying pans, rollers, etc., all adopt advanced manufacturing technology. The heating system of the frying pan adopts efficient heat exchange technology, which can quickly and uniformly heat the oil temperature, and can accurately control the temperature fluctuation within a very small range. The roller of the roller machine has high processing accuracy and smooth surface, which can ensure the uniform thickness of the noodles and improve the quality stability of the products.

It is also equipped with advanced automation control systems, such as PLC (Programmable Logic Controller) and touch screen operation interface. The PLC system can monitor and control various aspects of the fried instant production line in real time, including equipment start stop, speed adjustment, temperature control, etc. The touch screen operation interface makes it convenient for operators to set parameters and view device operating status, reducing the difficulty of operation.

B: Energy saving

The layout and process design of the entire fried instant production line are reasonable, reducing the transportation distance of materials and energy consumption in intermediate links. For example, the dough processing area, forming area, and frying area are closely connected, ensuring a smooth process from noodle processing to frying, avoiding unnecessary material handling and waiting time, and reducing energy consumption caused by frequent equipment start-up or prolonged idling.

C: Safety

The production line is equipped with complete safety operating procedures and warning signs. Clear danger warning signs are set up at key operating positions, such as the oil filler of the frying pan, high-temperature areas, and the inlet of the roller machine, to remind operators to pay attention to safety. At the same time, strict safety training should be provided to operators, including correct operating methods, emergency response measures, etc., to ensure that they can comply with safety regulations during the operation process and reduce the occurrence of safety accidents.

Features of fried Instant Noodle Production Line

1. The noodle blocks' shape is neat, the ripples and the color are uniform.

2. Finished products meet food safety requirements. The production process conforms to safety operation standard

3. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

4. The parts or equipment of every link of the equipment in the entire fried instant production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

5. All transmission parts of fried instant production line have outer shields to ensure safe operation without accidents.

Process technology parameter table, please select the product you are interested in based on production capacity or model

| Model | Production Capacity (70g/piece) | Installed Capacity | Steam Consumption | Workshop Requirements L×W×H(METER) |

| Model 1000(type) | 600(pcs/min) | 170KW | 4500kg/h | 130×8×6 |

| Model 900(type) | 540(pcs/min) | 170KW | 4000kg/h | 120×8×6 |

| Model 800(type) | 480(pcs/min) | 140KW | 3600kg/h | 110×6×6 |

| Model 700(type) | 420(pcs/min) | 130KW | 3100kg/h | 100×6×6 |

| Model 600(type) | 360(pcs/min) | 110KW | 2600kg/h | 100×6×6 |

| Model 500(type) | 300(pcs/min) | 80KW | 2200kg/h | 90×6×6 |

| Model 400(type) | 240(pcs/min) | 70KW | 1800kg/h | 90×6×6 |

| Model 300(type) | 126(pcs/min) | 60KW | 900kg/h | 85×6×6 |

| Model 200(type) | 84(pcs/min) | 50KW | 700kg/h | 80×6×6 |

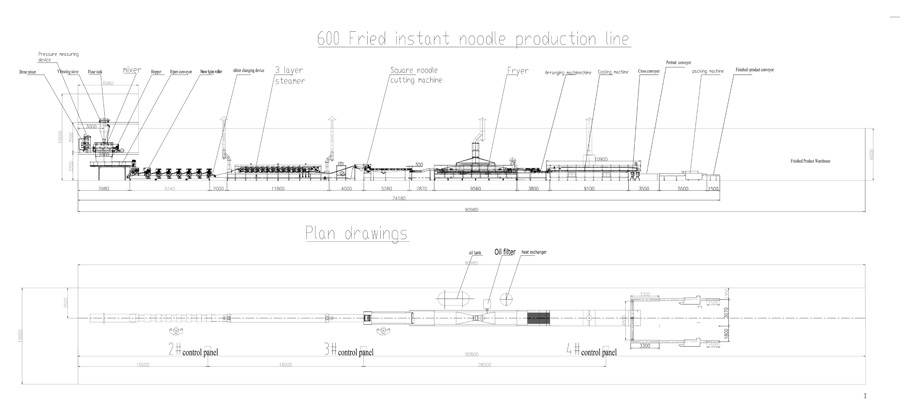

Production line process flow

Main unit machine pictures

Production line workshop layout

Production line video

Key words:

BFP600 Fried Instant Noodle Production Line

Fried Instant noodle production line

Layout

File size: 425.3KB

Upload Date:2025-05-19

Please leave us a message

Feel free to leave your contact information for more information