Chowmein Noodle Production Line Manufacturer

Classification:

Product Introduction

Product Details

Type 400 Fried Instant Noodles Machine Production Line

The fried instant noodle machine production line is a square noodle production line researched and developed by our company in 1990. After more than 30 years of continuous updating, replacement and improvement, it has become a series of products that are very popular among domestic and foreign customers. The size and gram weight of the noodle block can be adjusted. Each instant noodle production line can be equipped with two sets of noodle boxes, producing two various sizes of noodle blocks help customers increase the variety of noodle blocks. The degree of automation is higher, and the production from flour to finished products can be fully mechanized, with only 3 operators. The capacity can reach from60000pcs to 400,000 pcs/8h, which fully satisfy the needs of large enterprises.

The fried instant noodle making machine production line can produce many kinds of products, such as Indomie noodles, Nissin Foods, Maggi, MAMA, Wai Wai, Shin Ramyun, Master Kong, etc. Moreover, the instant noodle production line can also be customized according to the samples provided by the customer. This is an important reason why customers in more than 50 countries have been cooperating with our company for a long time.

Features of Instant Noodle making machine Production Line

1. The noodle blocks' shape is neat, the ripples and the color are uniform.

2. Finished products meet food safety requirements. The production process conforms to safety operation standard

3. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

4. The parts or equipment of every link of the equipment in the entire production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

5. All transmission parts have outer shields to ensure safe operation without accidents.

Technical parameters of instant noodle production line

output: 110,000bags/8H

roller pairs: 8 pairs

steam consumption:≥0.8Mpa;

Total Power:around 80KW not including packaging machine,380V,50Hz ;

Environment and working conditions of instant noodle production line

Industrial electricity, power supply, water and steam are required in the workshop.

Flow Chart

Brine mixer→Brine measuring device→Dual-axis Mixer→Aging machine→Compound roller→Multi-layer steamer→Square noodle cutting and dividing machine→Fryer→Cooling machine → Packing machine

Parameter, How many capacity are you interested in? I will send you the quotation list.

| model number | Capacity | Power | Steam consumption | Workshop for single layer steamer dimension(m) | Workshop for 3 layer steamer dimension(m) | Workers |

| BFP-200 | 40000bags/8H | 45KW | 1200-1300KG/H | 70*5*4 | 50*5*4 | 4 |

| BFP-300 | 60000bags/8H | 56 KW | 1200-1400KG/H | 75*5*4 | 60*5*4 | 4 |

| BFP-400 | 110000bags/8H | 83 KW | 1800-2000KG/H | 100*6*4 | 75*6*4 | 4 |

| BFP-500 | 140000bags/8H | 90 KW | 1800-2100KG/H | 100*6*4 | 75*6*4 | 4 |

| BFP-600 | 160000bags/8H | 106 KW | 2000-2200KG/H | 100*7*4.5 | 80*7*4.5 | 5 |

| BFP-700 | 200000bags/8H | 114 KW | 2400-2600KG/H | 110*8*4.5 | 80*8*4.5 | 5 |

| BFP-800 | 230000bags/8H | 125 KW | 2600-2800KG/H | 110*8*4.5 | 90*8*4.5 | 5 |

| workers:( not including packaging workers ) | ||||||

Product details

The 400 Type Roller Machine

The 400 new type Roller machine adopts a brand-new appearance design, which is beautiful and novel, giving people a completely new feeling. Adopting four-axis feeding, smooth feeding, ensuring the integrity of the noodle sheet, and excellent sheet forming effect; especially the effective combination of photoelectric tracking and automatic sheet feeding, which greatly reduces labor intensity

Waving

After the noodle strip is cutted by the slitter, it enters the pattern forming device, and after it comes out, it forms a wave

Multi-layer Steamer

Water-sealed multi-layer noodle steamer is a new product developed by our company. It has a smooth appearance and is water-tight and air-tight, which solves the problem that the traditional multi-layer steamer must be sealed with rubber strips

cutter and divider

The noodle cakes will be sent to the inlet of fryer by silica gel tray after cutting and folding, through sliding plate into stainless steel noodle boxes. We add the interval water spraying structure to ensure the noodle cakes into boxes smoothly. The improved folding device has advantages of low noise and flexible. It can still work properly when the speed of cutting achieving 500 pieces/min

Fryer

The fryer is the most critical equipment for producing instant noodles. The shape of the fryer is streamlined; the outer return of the noodle box reduces the height of the oil surface lengthens the oil drain section, adds strong oil blowers, and reduces the noodles oil content. 2-3% lower than similar products

Dual-axis Flour Mixing Machine

The place where flour and water are mixed and stirred. Dough mixing is the process of stirring flour and brine mixture in a certain proportion, so that the protein and starch in the flour absorb water and swell to form a flocculent dough. The flour mixer adopts a double-shaft structure, and the stirring paddle is in a spiral shape on the shaft. The two shafts rotate in opposite directions, so that the flour can fully absorb water and be uniform.

In addition to storing oil in the hydraulic system, the oil tank also plays the role of heat dissipation, separation of air bubbles in the oil, precipitation of impurities, and continuous oil supply.

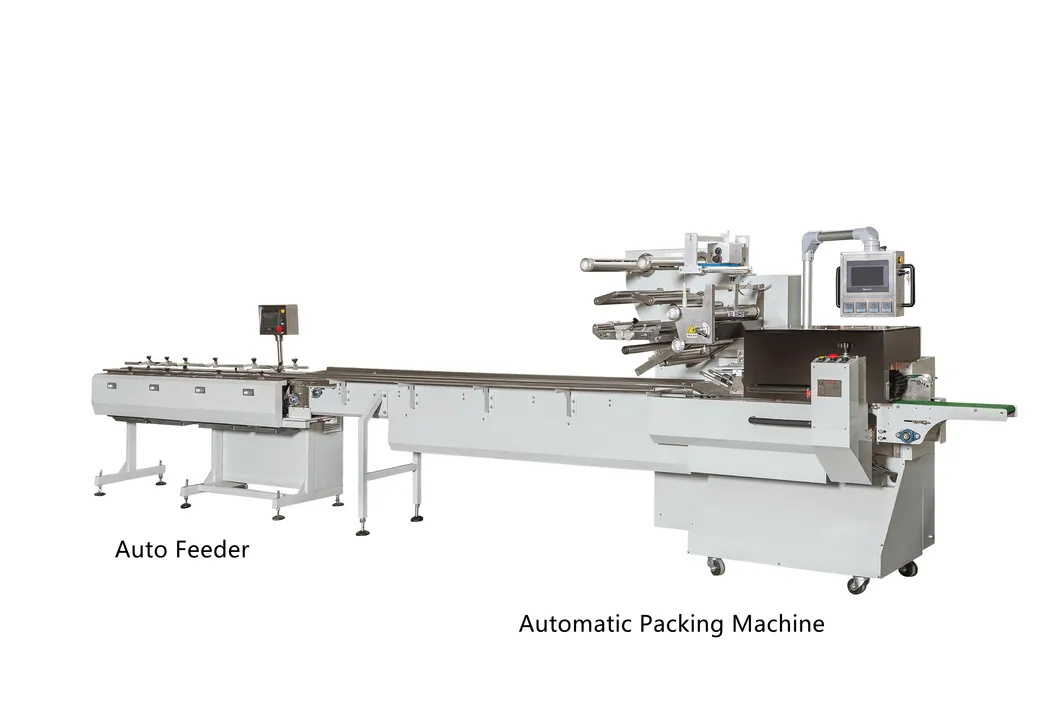

Packing machine

Automatic bag noodle packaging machine with printing of date of production and date of expiration of product

Auto feeder can make the noodle cakes into a line, automatically.

Key words:

Instant Noodle Machine

Layout

Please leave us a message

Feel free to leave your contact information for more information