Chowmein Noodles Machine Factory

Classification:

Product Introduction

After-sales Service: 1 Year

Warranty: 1 Year

Product Details

Are you looking for instant noodles production line?

you found it!

China's largest instant noodle production line manufacturer. With 45 years of production experience, we can manufacture various noodle production lines. Believe that we are your best choice!

Type 600 Fried Instant Noodles Making machine Production Line

Chow Mein (stir fried noodles) is a popular Chinese noodle dish, and its noodle processing equipment plays an important role in the food industry. The characteristics of these processing equipment are usually reflected in the following aspects:

Modern Chow Mein noodle processing equipment usually adopts automated production lines, which can achieve mechanized operations from raw material conveying, kneading, rolling, cutting to drying, packaging and other steps, greatly improving production efficiency.

The equipment can accurately control various process parameters, such as moisture content during kneading, thickness of rolling, width of cutting strips, etc., to ensure consistent taste and quality of noodles.

The equipment design complies with food safety and hygiene standards, is easy to clean and maintain, and ensures hygiene and safety during the production process. Some equipment also uses corrosion-resistant materials such as stainless steel to prevent cross contamination.

The Chow Mein noodle processing equipment can adapt to production needs of different scales and types, and can be applied from small family workshops to large-scale industrial production lines.

In summary, Chow Mein noodle processing equipment plays an important role in the food industry due to its high degree of automation, precise control, high efficiency and energy saving, hygiene and safety, multifunctionality, intelligent management, and environmental friendliness. These features not only improve production efficiency, but also ensure the quality and taste of noodles, meeting consumers' dual needs for deliciousness and health.

Technical parameters of instant noodle production line

output: 160000PCS/8H

roller pairs: 8 pairs

steam consumption:≥0.8Mpa;

Total Power:around 110KW not including packaging machine,380V,50Hz ;

Environment and working conditions of instant noodle production line

Industrial electricity, power supply, water and steam are required in the workshop.

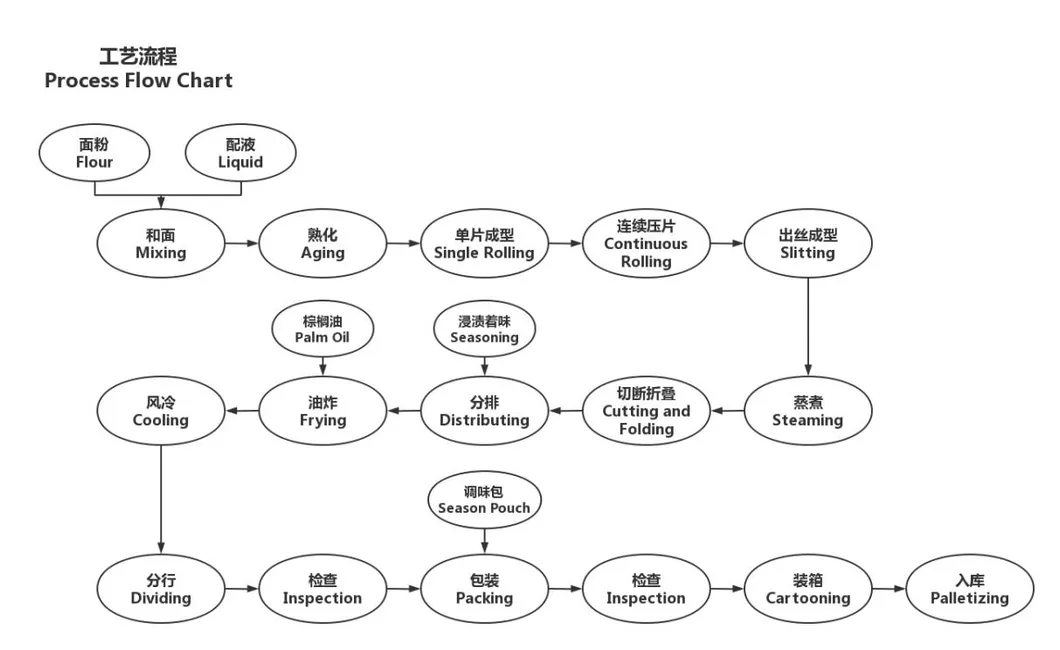

Flow Chart

This is the whole process of instant noodles production. The flour processing into instant noodles requires more than ten units to complete continuously, with a high degree of automation.

Brine mixer→Brine measuring device→Dual-axis Mixer→Aging machine→Compound roller→Multi-layer steamer→Square noodle cutting and dividing machine→Fryer→Cooling machine → Packing machine

Parameter

We choose the instant noodle production line according to the capacity. how many capacity are you interested in?

| model number | capacity | Power | Steam consumption | Workshop for single layer steamer dimension(m) | Workshop for 3 layer steamer dimension(m) | Workers |

| BFP-200 | 40000bags/8H | 45KW | 1200-1300KG/H | 70*5*4 | 50*5*4 | 4 |

| BFP-300 | 60000bags/8H | 56 KW | 1200-1400KG/H | 75*5*4 | 60*5*4 | 4 |

| BFP-400 | 110000bags/8H | 83 KW | 1800-2000KG/H | 100*6*4 | 75*6*4 | 4 |

| BFP-500 | 140000bags/8H | 90 KW | 1800-2100KG/H | 100*6*4 | 75*6*4 | 4 |

| BFP-600 | 160000bags/8H | 106 KW | 2000-2200KG/H | 100*7*4.5 | 80*7*4.5 | 5 |

| BFP-700 | 200000bags/8H | 114 KW | 2400-2600KG/H | 110*8*4.5 | 80*8*4.5 | 5 |

| BFP-800 | 230000bags/8H | 125 KW | 2600-2800KG/H | 110*8*4.5 | 90*8*4.5 | 5 |

| workers:( not including packaging workers ) | ||||||

Product Unit machine

Here are some important equipment, which are necessary for the production of instant noodles.

The 600 New Type Roller Machine

The 600 new type Roller machine adopts a brand-new appearance design, which is beautiful and novel, giving people a completely new feeling. Adopting four-axis feeding, smooth feeding, ensuring the integrity of the noodle sheet, and excellent sheet forming effect; especially the effective combination of photoelectric tracking and automatic sheet feeding, which greatly reduces labor intensity

Waving

After the noodle strip is cutted by the slitter, it enters the pattern forming device, and after it comes out, it forms a wave

Multi-layer Steamer

Water-sealed multi-layer noodle steamer is a new product developed by our company. It has a smooth appearance and is water-tight and air-tight, which solves the problem that the traditional multi-layer steamer must be sealed with rubber strips

cutter and divider

The noodle cakes will be sent to the inlet of fryer by silica gel tray after cutting and folding, through sliding plate into stainless steel noodle boxes. We add the interval water spraying structure to ensure the noodle cakes into boxes smoothly. The improved folding device has advantages of low noise and flexible. It can still work properly when the speed of cutting achieving 125-500 pieces/min

Fryer

The fryer is the most critical equipment for producing instant noodles. The shape of the fryer is streamlined; the outer return of the noodle box reduces the height of the oil surface lengthens the oil drain section, adds strong oil blowers, and reduces the noodles oil content. 2-3% lower than similar products

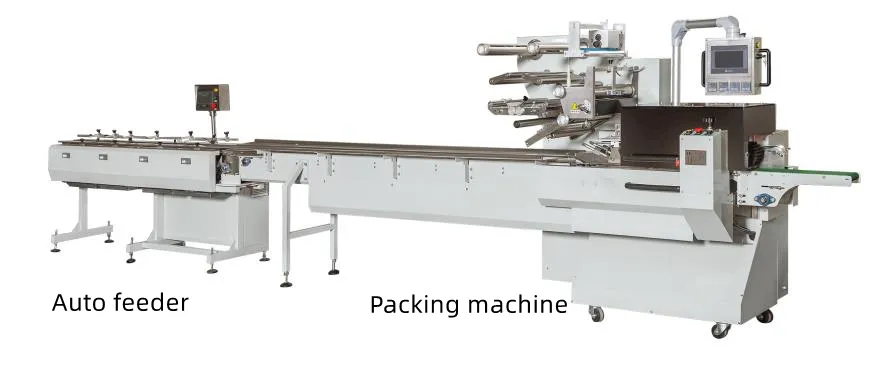

Packing machine

Automatic bag noodle packaging machine with printing of date of production and date of expiration of product

Auto feeder can make the noodle cakes into a line, automatically.

Key words:

Layout

Please leave us a message

Feel free to leave your contact information for more information