Egg Noodle Machine

Classification:

Product Introduction

After-sales Service: 1 Year

Warranty: 1 Year

Product Details

TYPE 1000 Fine Dried Noodles Production Line

The fully automatic noodle processing equipment is the core equipment of noodle production enterprises, which is mainly characterized by operational automation, efficiency, stability, and hygiene. The following is a detailed explanation of the specific characteristics:

1. High degree of automation: From automatic proportioning of raw materials (flour, water, etc.), kneading, curing, rolling, cutting, hanging, drying, cutting to packaging, the entire process can be mechanically completed continuously.

2. Adopt PLC (Programmable Logic Controller) or Industrial Internet of Things technology to achieve automatic adjustment and remote monitoring of parameters (temperature, humidity, time, etc.).

3. Fault warning: The equipment is equipped with sensors and alarm systems, which can detect abnormalities in real time and prompt maintenance, reducing downtime.

4. The equipment can operate continuously for 24 hours, with a daily output of 10 to 100 tons (depending on the model), greatly improving production efficiency.

5. Adopt variable frequency speed regulation technology and thermal energy recovery system (such as reusing drying waste heat) to reduce power consumption and steam consumption.

6. Core components (such as pressure rollers, cutting knives, etc.) are made of food grade stainless steel or special alloy steel, which is corrosion-resistant, wear-resistant, and extends equipment life.

7. The drying system is temperature controlled in different zones (such as low-temperature strip setting, medium temperature dehumidification, and high-temperature sterilization) to avoid surface breakage or deformation.

8. By changing the mold or adjusting the parameters, different widths, thicknesses, and shapes of hanging surfaces can be produced (such as round surfaces, flat surfaces, hollow surfaces, etc.).

summarize

The fully automatic noodle processing equipment helps enterprises achieve cost reduction, efficiency improvement, and quality enhancement through automation technology, energy-saving design, intelligent control, and high hygiene standards, especially suitable for medium and large noodle production enterprises and food processing plants. When selecting equipment, it is recommended to consider production capacity requirements, product types, and budget.

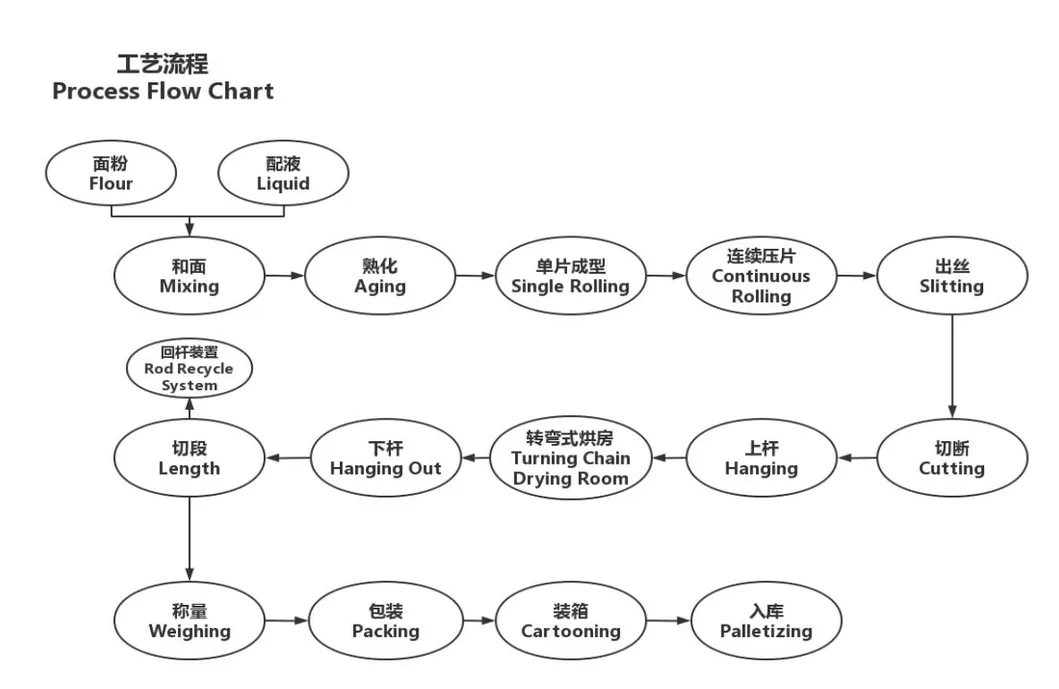

Production process

1. Main technical parameters:

(1) Output:40T/24h

(2) Roller pairs :9 pairs

(3) Total power :around 118 kw

(4) Stick noodles specification:width 1mm~6mm,thickness 0.8mm~1mm,ф1mm~1.5mm

(5) Stick noodle length :200,240mm adjustable

(6) Drying time:4h~4.5h

2.Product list for you to choose from

| Model | Power | Capacity | Workshop dimension(m) | Workshop dimension(m) | Workers | |

| 350 | 47KW | 500KG/H | 66*9*4.5(+3.5) | 40*7*4(+3.5) | 5 | |

| 450 | 58 KW | 600 KG/H | 70*11*4.5(+3.5) | 50*8*4(+3.5) | 6 | |

| 550 | 63 KW | 750 KG/H | 75*12*4.5(+3.5) | 65*9*4(+3.5) | 7 | |

| 650 | 78 KW | 1100 KG/H | 90*14*4.5(+3.5) | 65*10*4(+3.5) | 7 | |

| 765 | 90 KW | 1200 KG/H | 115*16*4.5(+3.5) | 70*10*4.5(+3.5) | 8 | |

| 850 | 98 KW | 1500 KG/H | 70*11*4.5(+3.5) | 9 | ||

| 1000 | 118 KW | 1700 KG/H | 70*12*4.5(+3.5) | 9 | ||

| 1500 | 300KW | 3500KG/H | 85*12*4.5(+3.5) | 9 | ||

| workers:( not including packaging workers ) | ||||||

3. Details of Main Product

Rolling Machine

Rolling Machine adopt different diameter roller rolling, is advantageous to the gluten forming;Ripple roller rolling,make the dough sheet draging in multi directions. improve the dough sheet quality. each roller adopt independent driving. Effectively guarantee the reliability of the transmission, and the structure is simplified, easy to maintenance.

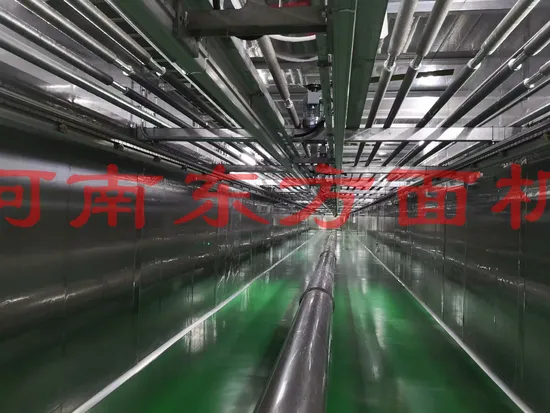

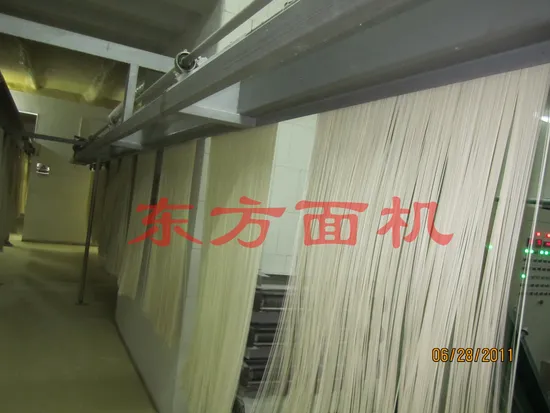

Automatic drying room 1

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying;Through frequncy control adjusting the humidity and tempreture of each drying section, convenient and reliable; Clever drying room design can make the both end humid air flow toward the middle, , reduce the energy consumption 20-30%.

Automatic drying room 2

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying;Through frequncy control adjusting the humidity and tempreture of each drying section, convenient and reliable; Clever drying room design can make the both end humid air flow toward the middle, , reduce the energy consumption 20-30%.

Key words:

Layout

Please leave us a message

Feel free to leave your contact information for more information