Fried Chowmein Noodle Production Line

Classification:

Product Introduction

After-sales Service: 1 Year

Warranty: 1 Year

Product Details

1. FRIED ROUND INSTANT NOODLE PRODUCTION LINE

The instant noodle production line is composed of brine mixer, brine measuring device, dual-axis mixer, round shape aging machine, compound roller, single layer steamer, round noodle cutting and dividing machine (two times stretching), fryer, cooling machine, conveyor and other equipment connected. The whole line is frequency controlled and PLC controlled.

2. Introduction of instant noodle production line

Our company develops the fried round instant noodle production line according to the market demand. The whole production line realizes the perfect combination of mechanical and electrical integration. It is the current technologically advanced fried round instant noodle production equipment. It can meet the consumers' need for instant noodles even when they can't cook conveniently or have enough time to eat. It's convenient and doesn't reduce the grade. It's a necessary food for business trip and tourism, ready to brew and eat any time. The finished product is round, mainly in bowl, and the weight of the noodle cake is about 70g (adjustable).

3. Technical parameter

output: 130000-200000 pcs/8h;

roller pairs : 8pairs;

Steam consumption: 2800kg/h,steam pressure≥0.8Mpa;

Installed capacity: around 100KW(not including packaging machine),380V,50Hz.

4. Parameter

| Capacity | Power | Steam consumption | Workshop for single layer steamer dimension(m) | Workshop for three layer steamer dimension(m) | Workers |

| 60000/8H | 56 KW | 1200-1400KG/H | 75*5*4 | 60*5*4 | 4 |

| 80000/8H | 68 KW | 1300-1500KG/H | 80*6*4 | 65**4 | 4 |

| 100000/8H | 80 KW | 1400-1600KG/H | 90*6*4 | 70*6*4 | 4 |

| 120000/8H | 83 KW | 1800-2200KG/H | 100*6*4 | 75*6*4 | 5 |

| 160000/8H | 106 KW | 2000-2200KG/H | 100*7*4.5 | 80*7*4.5 | 5 |

| 200000/8H | 114 KW | 2400-2600KG/H | 110*8*4.5 | 80*8*4.5 | 5 |

| workers:( not including packaging workers ) | |||||

5.Product introduction

Roller

The single rollers shown in picture is currently the largest capacity crisp noodle production line. With a roller width of 1000 mm, The continuous rollers with independent power control, its bearings can be removed quickly, to achieve the reliable transmission and simplified structure in maintain.

Steamer

The multi-layer steamer adopts water-sealing structure, with strong sealing ability and no steam leakage. The lifting type doors, make the cleaing easily; The inner of steamer with the reasonable spraying pipes, so that gelatinization is more effective.

Cutter and divider

The improved folding device has advantages of low noise and flexible. It can still work properly when the speed of cutting achieving 500 pieces/min.

Fryer

Fryer is the key unit equipment of fried instant noodle production. The fryer shown in picture lowers the oil level height, lengthens the drain part and increases the oil removal device, and all these changes greatly reduce the oil content of noodle cakes, which is 2%-3% lower than similar products.

Cooling mahcine

Dried noodle cakes move forward into the air cooling machine, which shares same mesh belt with dryer. Cool air from several axial fans under the mesh belt goes through the noodle cakes and is discharged to outdoor by upper exhausted fans.

Distributing conveyor and packing

After cooling, the noodle cakes slides down to conveyor belt by T-shaped plate, then distributs into several separate lines into the packaging machine.

Key words:

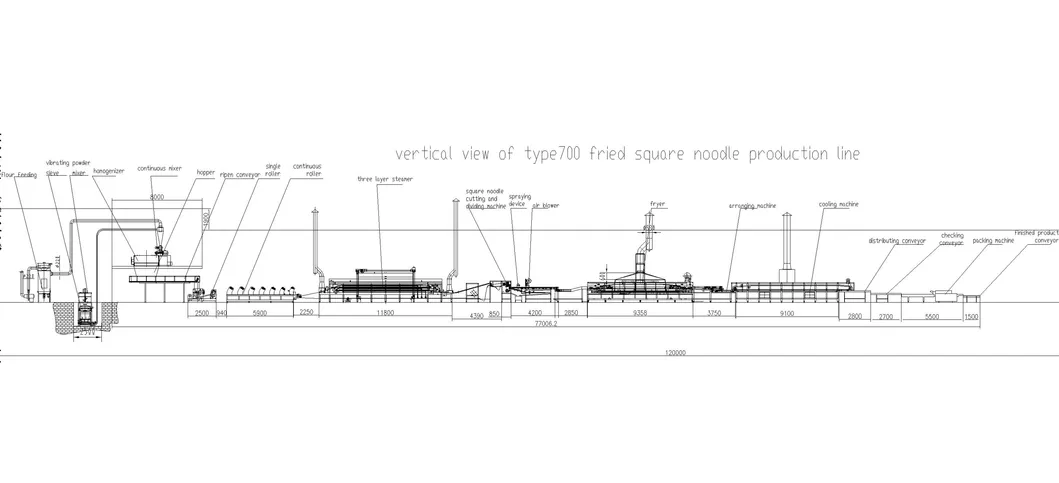

Layout

Please leave us a message

Feel free to leave your contact information for more information