Full Automatic Air Dried Noodles Making Machine

Classification:

Product Introduction

After-sales Service: 10 Years

Warranty: 1 Year

Product Details

Function of Non-fried instant noodle production line

The fully automated non fried hot air drying instant noodle production line gathers the essence of modern food processing technology, aiming to improve production efficiency, ensure product quality and reduce manual operation. Its main characteristics can be summarized as follows:

1. This production line adopts advanced automation control system, which can continuously complete the entire process from dough forming, hot air drying to packaging.

2. Equipped with intelligent sensors and monitoring systems, it can monitor various parameters in real-time during the production process, such as temperature, humidity, cake thickness, etc., to ensure product consistency and stability.

3. The use of hot air drying technology instead of traditional frying process not only reduces the oil content, but also meets the needs of modern consumers for a healthy diet.

Hot air drying can evenly and quickly remove moisture from the dough, maintain the elasticity and taste of the noodles, and reduce the loss of nutrients.

4. The production line adopts an efficient energy management system to optimize energy consumption during the hot air drying process and reduce operating costs.

5. The introduction of automated production lines has significantly reduced manual operations and lowered labor costs.

6. The operation is simple, and employees can start working after short-term training, which improves production efficiency.

Features of Instant Noodle Production Line

1. The noodle blocks' shape is neat, the ripples and the color are uniform.

2. Fast production, large capacity, Steam saving, and low oil consumption.

3. Finished products meet food safety requirements. The production process conforms to safety operation standard

4. Good stability, low failure rate, simple operation and beautiful appearance.

5. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

6. The parts or equipment of every link of the equipment in the entire production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

7. All transmission parts have outer shields to ensure safe operation without accidents.

Our company has a complete the system of QoS(Quality of Service) guarantee including product development, manufacturing, pre-sales and after-sales . While manufacturing high-quality instant noodle production lines for customers, we also provide users with comprehensive services.

Pre-sale: Plant area planning; drawing production line layout; Selection of supporting equipment, purchasing; Product positioning analysis.

After-sales: Send installers to the site to install and debug the production line to produce qualified noodles; Training users how to operate the production line, maintenance, and production management; Free lifetime telephone consultation.

Main features of non-fried instant noodles production line:

1. The noodles produced have uniform micro expansion, good rehydration;

2. High output and good stability;

3. The whole production line adopts PLC interface control, which is easy to operate;

4. Automatic into-box, save manual work and speeding up work efficiency;

Main production models: 60000 pcs/ 8h, 80000 pcs/ 8h, 100000pcs/ 8h, 120000pcs/ 8h, 160000pcs / 8h

This series of products have the characteristics of new technology, reasonable technology, stable operation and convenient maintenance. And be responsible for installation, commissioning equipment and training operators.

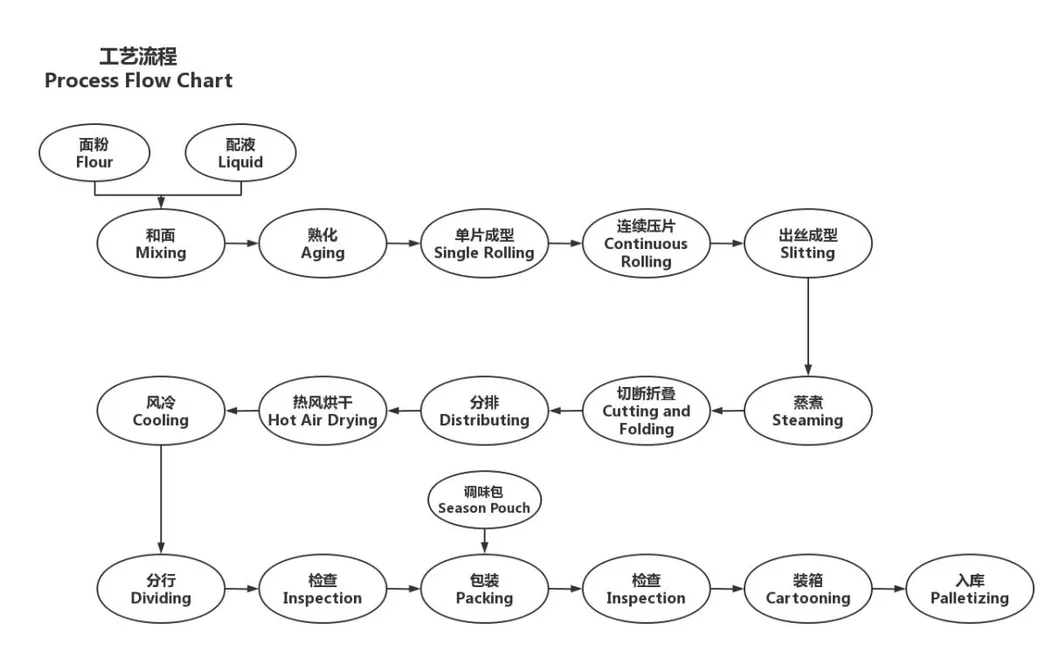

Production process

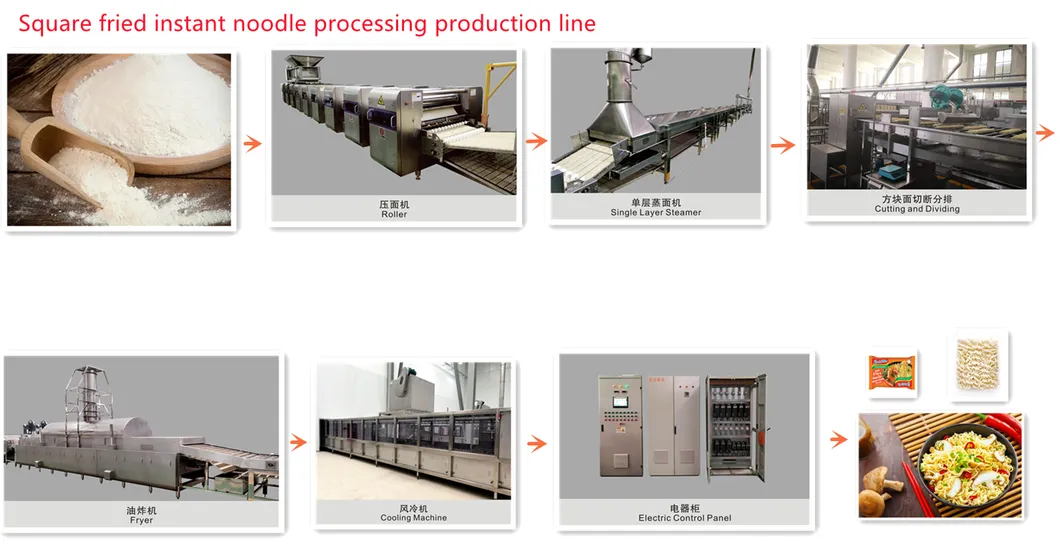

Main Unit Machine

Roller

The new type roller machine adopts an integral structure, the front and back are integrated, and the middle is uninterrupted. It consists of a feeding hopper, a feeding shaft, multiple groups of pressing rollers and the slitter device. The feeding shaft adopts four axis to make the feeding process continuous and uniform. The flour passes through the first group of roller to form a dough sheet, then the dough sheet is continuously rolled by the roller machine, and finally the dough sheet becomes a suitable thickness, which has the characteristics of smoothness and strong toughness. Each group of new pressure rollers adopts individual power, frequency control of motor speed, and alloy materials.

Noodle Steamer

The corrugated noodles are sent into the steamer with a mesh belt, and the noodles are gelatinized by steam heating, and the shape of the corrugated noodle is fixed.The steam box adopts a water-sealing structure to ensure that the steam does not leak. The upper cover can be lifted and lowered as a whole, which is convenient for cleaning. The mesh belt is made of stainless steel, which is safe and hygienic. Three-layer structure covers a small area.

Dryer

This dryer is the latest type of recent years, which adopts hot air drying technology. It improves the wind speed and temperature, also can ensure relative stability of noodle cakes, without shifting. The maximum temperature can reach 150 ºC, the scientific hot air circulation system makes full use of the heating energy, improves the baking effect. There are two zones, first zone 3 layer 18m, second zone 5layer 18m, include below two layer is cooling 9 mins. In general, drying time reaches about 40 minutes. The moisture content of non-fried instant noodles made is less than 10%, which is less than fried instant noodle.

conveyor of finished products

The noodle blocks are conveyed vertically, and only one noodle piece is allowed to pass at a time, which is convenient for manual or machine inspection and adjustment.

Key words:

Fried Instant noodle production line

Layout

Please leave us a message

Feel free to leave your contact information for more information