Mixing machine

Hakka noodle making machine

Classification:

Product Introduction

Product Details

Hakka Noodle Production Line

The non fried handmade Hakka noodles production line is our company's traditional product, the shape of the noodles is manual formed and can be made into any shape, which is relatively flexible, this is also the characteristic of the noodle production line,other features and investment market prospects of the noodle production line are as follows:

1. Strong adaptability to raw materials: Generally, the gluten requirements for flour are relatively broad, ranging from 28% to 35%, to adapt to different raw material characteristics, allowing enterprises to flexibly choose flour according to market demand and raw material supply, and reduce production costs.

2. Unique processing technology: Using high-pressure steamer cooking technology, it can effectively improve the degree of noodle conversion, making the product beautiful and generous in appearance, slightly yellow and transparent, with a strong and refreshing taste. When cooking, it does not mix the soup and retains the traditional flavor and taste characteristics of noodles.

3. Partial automation of the production process: Mechanization and automation have been achieved in processes such as flour mixing, conveying, and drying, improving production efficiency and reducing manual labor intensity. However, manual operation is still required in the dough forming process, ensuring the handmade characteristics and flexibility of the product.

4. Product nutrition and health: The non fried processing method avoids problems such as high oil content, high calorie content, and possible harmful substances in fried foods, which is more in line with modern consumers' demand for healthy eating and helps companies build a brand image of healthy food.

5. With the continuous improvement of people's health awareness, the demand for non fried, additive free, and nutrient rich foods is becoming increasingly strong. As a non fried instant noodle product, the hand plate fits this consumer trend and has great market potential.

6. The handmade process and distinctive flavor of traditional noodles are preserved on the hand plate, which has unique advantages in inheriting and promoting Chinese culinary culture. With the rise of the cultural consumption market, food with local characteristics and cultural connotations is more favored by consumers. Handmade noodles are expected to become a carrier for inheriting and promoting local food culture, further expanding market share.

7. Market segmentation and differentiated competition: In the fiercely competitive food market, the handmade noodles can stand out through differentiated competition strategies. For example, various flavors, shapes, and packaging specifications of products have been developed for different consumer groups and needs, such as children's handmade noodles, carrot handmade noodles, spinach handmade noodles, etc., to meet the personalized needs of different consumers and achieve market segmentation and precision marketing.

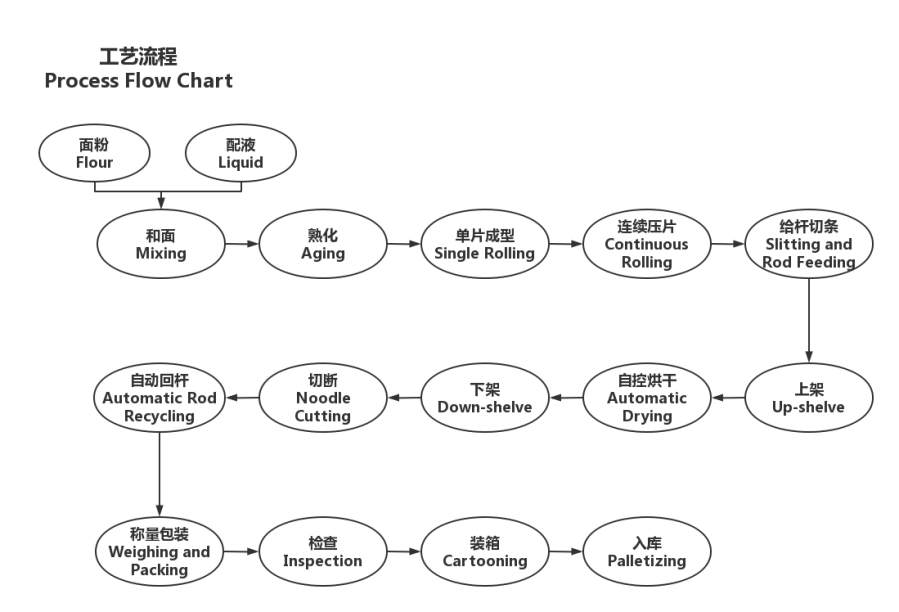

1 The process of hand-formed noodles:

Material——Mixing——dough aging——Single Sheet Rolling—— Continuous Rolling——Slitting——Pre-drying——Hand Forming—— Drying——Cooling——Packaging——Finished Product

2 The main equipment of the hand-formed noodle production line is composed of:

1. Double -axis mixing machine;

2. Ripening conveyor

3. Single Roller

4. Continuous Roller

5. Slitting machine

6. Pre-drying (Autoclave)

7. Hand Formed

8. Drying (Single-layer dryer)

9. Cooling Machine

Process technology parameter table, please select the product you are interested in based on production capacity or model

| CAPACITY | POWER | STEAM CONSUMPTION | MACHINE DIMENTION | WORKSHOP DIMENTION | WORKERS |

| 3T/8H | 48KW | 900~1100KG/H | 58x2x4.5 | 80x5×4.5 | 15 |

| 5T/8H | 63KW | 1100~1300KG/H | 62×2.2x4.5 | 90x7x4.5 | 25 |

| 7T/8H | 87KW | 1200~1400KG/H | 88x2.5x4.5 | 100x7x4.5 | 28 |

| 10T/8H | 96KW | 1300~1500KG/H | 90x2.8x4.5 | 100x7x4.5 | 30 |

| Note: The number of workers is the number of people per shift, excluding packaging staff.(WORKERS:NOT INCLUDING PACKAGING WORKERS) | |||||

Production line process flow

Main unit machine pictures

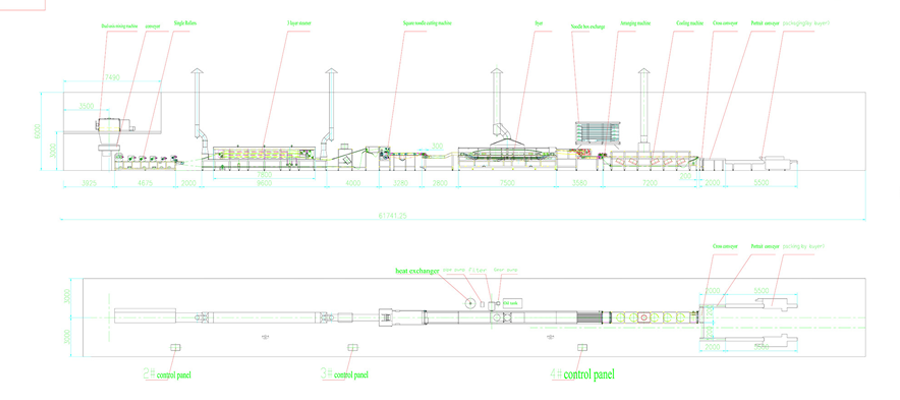

Production line workshop layout

Production line video

Key words:

Hakka noodle making machine

Layout

File size: 499.8KB

Upload Date:2025-05-19

Please leave us a message

Feel free to leave your contact information for more information