Dough mixer

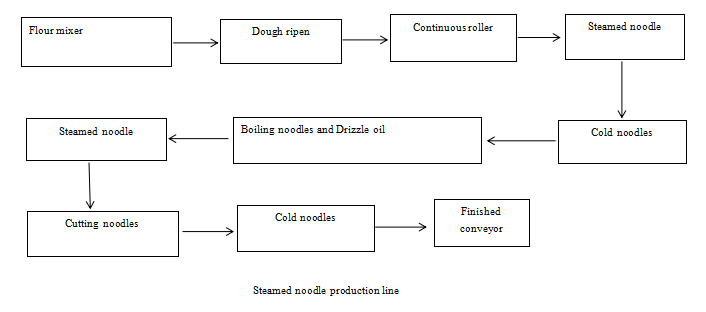

Steamed noodle production line

Classification:

Product Introduction

Product Details

the steamed and cooked noodle production line

The noodles processed by the steamed and cooked noodle production line are very similar to Japanese udon noodles. They are steamed or cooked and then cooled and packaged. The noodles have a high moisture content and a very good taste, making cooking very convenient. They are very popular noodles in Asia. The characteristics and market prospects of our company's cooked noodle production line are as follows:

1、 Characteristics of steamed and cooked noodle production line

(1) Advanced processing technology

A. The production line adopts advanced cooking technology, which can accurately control the cooking time and temperature of noodles, ensuring uniform maturation of noodles. Make the noodles softer, smoother, and more similar in taste to Japanese udon noodles.

B. Cool the cooked noodles to a temperature suitable for packaging, which can maintain the quality of the noodles, effectively extend their shelf life, reduce the growth of microorganisms, and ensure the safety and stability of the product.

(2) High degree of automation

A. The production line has achieved fully automated operations from flour feeding, kneading, pressing, cutting, steaming, cooling, oiling, loosening to packaging, greatly reducing manual labor and improving production efficiency and product consistency.

(3) Large and stable output

A. The cooked noodle production line has a high production capacity, capable of producing 500kg-2000kg of cooked noodles per hour, which can meet the demand of large, medium, and small-scale markets.

(4) Product quality, safety and reliability

A. Strictly follow food safety standards and hygiene regulations during the production process. Multiple inspection procedures are set up, such as appearance inspection, weight inspection, microbiological testing, etc., to ensure product quality, safety, and reliability.

B. The production workshop adopts advanced air purification systems and disinfection equipment, effectively reducing the pollution of bacteria, dust and other pollutants in the air to the products, allowing consumers to consume with confidence.

2、 Market prospects

A. Asian market: The Asian region is one of the main consumer markets for cooked noodles, especially in countries such as Japan and South Korea, where products like udon have a strong consumer base and cultural background. Due to the close similarity in taste and quality between cooked noodles produced in our country and udon noodles, as well as their price advantage and rich taste options, they can be used as substitutes or supplements to udon noodles to enter these markets. Opening cooked noodle specialty stores or collaborating with local catering enterprises in cities and tourist destinations in some Asian countries to provide cooked noodle dishes with Chinese characteristics can attract a large number of tourists and local residents, spread Chinese food culture, and expand international market share.

B. European and American markets: In recent years, with the increasing popularity and popularity of Asian cuisine in Europe and America, cooked noodles, as a unique flavor of Asian food, have gradually attracted the attention of European and American consumers. In big cities and Chinese communities in Europe and America, there have been some supermarkets and specialty stores selling Asian food, and cooked noodles, as one of the products, are gradually increasing in market demand. In addition, by collaborating with local catering enterprises and food importers, introducing cooked noodles to more restaurants and family tables, meeting the curiosity and exploratory desire of European and American consumers for Chinese cuisine, and further exploring the European and American markets has great potential.

In summary, the products produced by the cooked noodle production line have many advantages and characteristics, and have broad market prospects. There is significant development space in both domestic and international markets. In the future market competition, enterprises should continuously optimize production processes, improve product quality, strengthen brand building and market promotion to meet the increasingly diverse needs of consumers and achieve sustainable development of the enterprise.

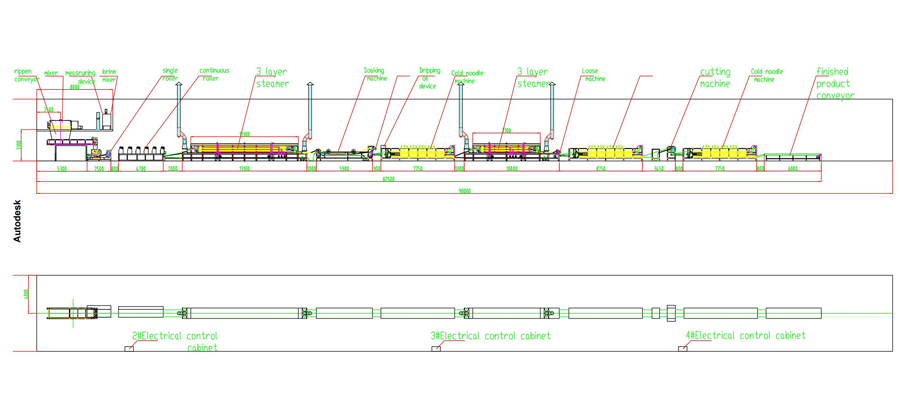

1. Continuous mixer

The Ripen fresh noodle production is very similar with fried noodle line,through flour feeding,continuous mixing,aging,rolling ect. Process, noodle sheet was created.

1、Continuous rollers

Rolling machine adopt nichrome roller,high hardness,smooth roller surface,make the dough sheet Flat and smooth.

2、 Steamer machine

The rolled dough sheets, after slitting, falling down and accumulate onto the steamer mesh as a certain gap, to form large ripple;then into the steamer,the steamer Counter weight of opening was added to the side door of traditional steamer. The redesign of the layout of the steamer pipe improved paste effect. Also our company newly lauch a new design multilayer steamer adopt lifting cover open,and use water seal technology, Convenient, energy saving, easy to clean

3、Noodle soaking tank

After steaming the noodle will soak a period of time, which allows noodles to fully absorb water and ensures the water content of the product.

4、Noodle cooling machine

After soaking the noodles go through a high-speed rotating drum for loosing, and then use the drop cloth curtain to wipe oil on the noodle, and then after a period of rest, to achieve dry and anti-paste.

5、Three layer steamer

The noodles will stand after a period of time and then steaming for a second time for further maturation and sterilization

6、Cutting machine

The noodles will be cut at a certain length for weighing and bagging.

7、cooling machine

Cut noodles move on into the air cooling machine, cool air from several axial fans under the mesh belt goes through the noodles and is discharged to outdoor by centrifugal fan.

8、Noodle conveyor

After cooling the noodles will be sent through turning machine onto the conveyor for weighing and packaging.

Production line process flow

Process technology parameter table, please select the product you are interested in based on production capacity or model

Model | Production Capacity | Installed Capacity | Steam Consumption | Workshop Requirements |

SN300 | 4T/8H | 80KW | 600-800kg/h | 70*5*6 |

SN400 | 6T/8H | 105KW | 1000-1200kg/h | 75*5*6 |

SN500 | 8T/8H | 130KW | 1400-1600kg/h | 85*8*6 |

SN600 | 10T/8H | 150KW | 2000-2200kg/h | 95*8*6 |

SN800 | 13T/8H | 160KW | 2800-3000kg/h | 105*8*6 |

SN1000 | 15T/8H | 180KW | 3200-3400kg/h | 115*8*6 |

Main unit machine pictures

Production line workshop layout

Production line video

Key words:

Steamed noodle production line

Fresh noodle production line

Layout

File size: 416.2KB

Upload Date:2025-05-19

Please leave us a message

Feel free to leave your contact information for more information