Instant Cup Noodles Processing Production Line Manufacturer in China

Classification:

Product Introduction

After-sales Service: 1 Year

Warranty: 1 Year

Product Details

1. professional instant cup noodles production line

According to the requirements of many foreign customers, our company has increased the investment in research and development of the fried instant noodle production line, improved the automation of the instant noodle production line, and greatly changed the product performance and appearance, especially the round instant noodle(cup noodle) production line. Its maximum production capacity per minute can reach 420 pieces, with obvious characteristics such as high efficiency, energy saving and small covering areas. The round instant noodle produced is golden in color, beautiful in appearance and smooth in taste, and has been recognized and praised by foreign customers. The produced noodles can be made into cup noodles, bowl noodles or bag noodles, and the packaging forms are various to meet the needs of different consumers.

High degree of automation, only 3 workers;

Product diversification: divided by capacity, 60,000 pcs/8 h, 80,000 pcs/8 h, 100,000 pcs/8 h, 120,000 pcs/8 h, 160,000 pcs/8 h etc. Customers can choose a production line with suitable capacity according to sales and market.

Because our company is a professional manufacturer in China, we can also customize the equipment according to the user's requirements or samples.

Features of Instant Cup Noodles Production Line

1. The noodle blocks' shape is neat, the ripples and the color are uniform.

2. Fast production, large capacity, Steam saving, and low oil consumption.

3. Finished products meet food safety requirements. The production process conforms to safety operation standard

4. Good stability, low failure rate, simple operation and beautiful appearance.

5. PLC programmable controller realizes the full automation control of the production process, the synchronous speed regulation of the whole line of equipment, the monitoring and management of the data of a single equipment, and the remote cross-border monitoring can be realized through the Internet.

6. The parts or equipment of every link of the equipment in the entire production line in contact with food conform the requirements of FDA(Food and Drug Administration) food machinery. 304 stainless steel or food-grade materials are used to ensure the safety and health of noodle food.

7. All transmission parts have outer shields to ensure safe operation without accidents.

Our company has a complete the system of QoS(Quality of Service) guarantee including product development, manufacturing, pre-sales and after-sales . While manufacturing high-quality instant noodle production lines for customers, we also provide users with comprehensive services.

Pre-sale: Plant area planning; drawing production line layout; Selection of supporting equipment, purchasing; Product positioning analysis.

After-sales: Send installers to the site to install and debug the production line to produce qualified noodles; Training users how to operate the production line, maintenance, and production management; Free lifetime telephone consultation.

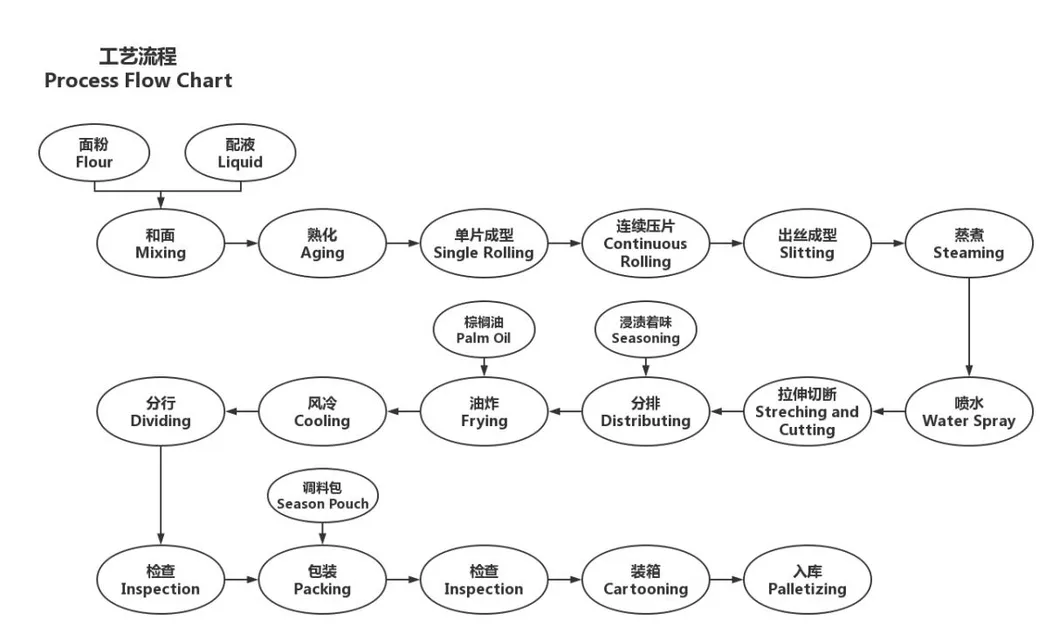

2. Production processof fried instant cup noodle production line

The instant cup noodle production line is composed of brine mixer, brine measuring device, dual-axis mixer, round shape aging machine, compound roller, single layer steamer, round noodle cutting and dividing machine (two times stretching), fryer, cooling machine, conveyor and other equipment connected. The whole line is frequency controlled and PLC controlled.

3. Technical parameter

output: 60000-160000 pcs/8h;

roller pairs : 8pairs;

Steam consumption: 1000-2800kg/h,steam pressure≥0.8Mpa;

Installed capacity: around 100KW(not including packaging machine),380V,50Hz.

4. Product list for you to choose from

| Capacity | Power | Steam consumption | Workshop for single layer steamer dimension(m) | Workshop for three layer steamer dimension(m) | Workers |

| 60000pcs/8H | 56 KW | 1200-1400KG/H | 75*5*4 | 60*5*4 | 4 |

| 80000pcs/8H | 68 KW | 1300-1500KG/H | 80*6*4 | 65**4 | 4 |

| 100000pcs/8H | 80 KW | 1400-1600KG/H | 90*6*4 | 70*6*4 | 4 |

| 120000pcs/8H | 83 KW | 1800-2200KG/H | 100*6*4 | 75*6*4 | 5 |

| 160000pcs/8H | 106 KW | 2000-2200KG/H | 100*7*4.5 | 80*7*4.5 | 5 |

| 200000pcs/8H | 114 KW | 2400-2600KG/H | 110*8*4.5 | 80*8*4.5 | 5 |

| workers:( not including packaging workers ) | |||||

5. product details

Aging Conveyor

Aging conveyor adopts the dough first-in-first-out conveying method to ensure the process stability; the dough is stationary on the conveyor belt, heat preservation, moisturizing, and natural aging; the dough does not sticky after being broken, and it enters the gap of the roller very smoothly; make noodle taste chewy and smooth.

The 800 New Type Roller Machine

The 800 new type Roller machine adopts a brand-new appearance design, which is beautiful and novel, giving people a completely new feeling. Adopting four-axis feeding, smooth feeding, ensuring the integrity of the noodle sheet, and excellent sheet forming effect; especially the effective combination of photoelectric tracking and automatic sheet feeding, which greatly reduces labor intensity

Waving

After the noodle strip is cutted by the slitter, it enters the pattern forming device, and after it comes out, it forms a wave

Multi-layer Steamer

Water-sealed multi-layer noodle steamer is a new product developed by our company. It has a smooth appearance and is water-tight and air-tight, which solves the problem that the traditional multi-layer steamer must be sealed with rubber strips. The internal steam pipes are carefully arranged to ensure the gelatinization effect and save a lot of steam. The upper cover can be lifted open. Make it easy and fast internal sanitation and cleaning.

Round noodle cutting machine

The steamed noodles are cut to a fixed length after being sprayed by waterfall and with three times stretching, and then fall into the noodle box through the sliding floating bucket. The noodles can be stretched for three times to basically straighten the noodles, which provides good conditions for the automatic shaping machine in the subsequent process. The polymer splitter completely separates the noodles, and the new floating bucket can ensure that each noodle accurately falls into the center of the noodle box.

Blowing shaping machine

The automatic air blowing and shaping machine is a product designed to replace labor. The rotating head rotates while blowing air to achieve the purpose of blowing and shaping the noodles. The shaping process is fully automated, stable and reliable

Fryer

The fryer is the most critical equipment for producing instant noodles. The shape of the fryer is streamlined; the outer return of the noodle box reduces the height of the oil surface lengthens the oil drain section, adds strong oil blowers, and reduces the noodles oil content. 2-3% lower than similar products

Air-cooler machine

The noodles enter the air-cooler, and they are blown quickly to cool down. Beautiful and smooth appearance, almost perfect internal design, overall, stylish and completely new. Two blowers on one side send air in, and an exhaust fan on the top exhausts the hot air outside. The arranging bar carries the noodles, which runs smoothly, neatly, and sanitarily.

Key words:

Fried Instant noodle production line

Layout

Please leave us a message

Feel free to leave your contact information for more information