Instant Noodle Food Production Line Machine Having a High Efficiency

Classification:

Product Introduction

After-sales Service: 10 Years

Warranty: 1 Year

Product Details

Fried square instant noodle production line

The fried instant noodle production line is an integrated, fully automatic instant noodle production line that encompasses dough mixing, aging, rolling, cutting, steaming, frying, and cooling processes. It features a modular design, achieving full-process automation from raw materials to finished products, making it an ideal choice for modern instant noodle manufacturing companies to increase production capacity and ensure product quality.

Product Features:

- PLC intelligent control system for precise automated production.

- Touchscreen interface for simple and user-friendly operation, reducing the difficulty of operation.

2. High Production Capacity

- A production capacity of up to 160,000 packs in 8 hours, meeting the demands of large-scale production.

- A quick mold change system to flexibly adapt to market changes.

3. Precise Process Control

- Vacuum mixing, multi-stage rolling, and precise cutting to ensure noodle quality.

- Intelligent temperature control system to guarantee the effect of steaming and frying.

Main Parameter of different models:

| Model | Production Capacity | Installation Capacity | Steam Consumption | Workshop Requirements L*W*H(meter) |

| 1000 type | 420 pcs/min | 180KW | 2800kg/h | 130*8*6 |

| 900 type | 360 pcs/min | 180KW | 2400kg/h | 130*8*6 |

| 800 type | 330 pcs/min | 150KW | 2200kg/h | 120*6*6 |

| 700 type | 290 pcs/min | 140KW | 1900kg/h | 120*6*6 |

| 600 type | 250 pcs/min | 120KW | 1700kg/h | 110*6*6 |

| 500 type | 208 pcs/min | 90KW | 1400kg/h | 110*6*6 |

Technical parameters of 600 model:

| Production capacity | About 120,000bags/8h, 70g | Frying times | 90s |

| Noodle cake shape | Square shape | Equipment Dimension | About L95×W5×H5 |

| Roller width | 600mm | Workshop requirement | About L110×w6×h6 |

| Flour mixing time | About15min/time | Electric three phase | 380v/50hz,three phase |

| Aging time | About15min/time | Delivery time | 90days |

| Steam consumption | 1700kg/h | Warranty | 1 year |

| Steam boiler | 2 tons by user | Total power | About 120KW |

| Steam Pressure | 0.8Mpa | Payment term | EXW or FOB |

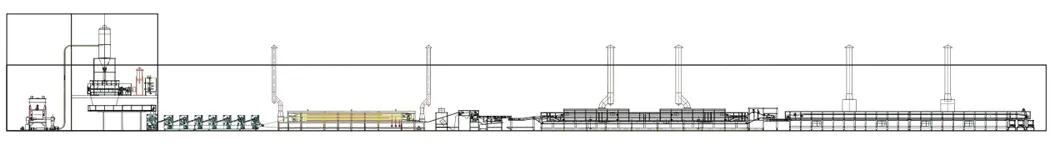

Overall layout:

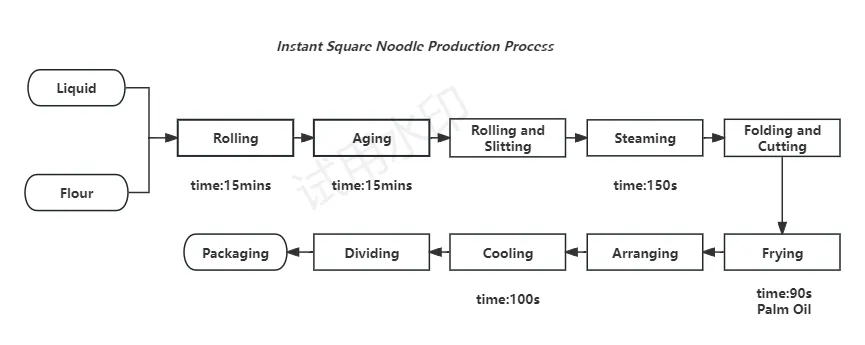

Production process:

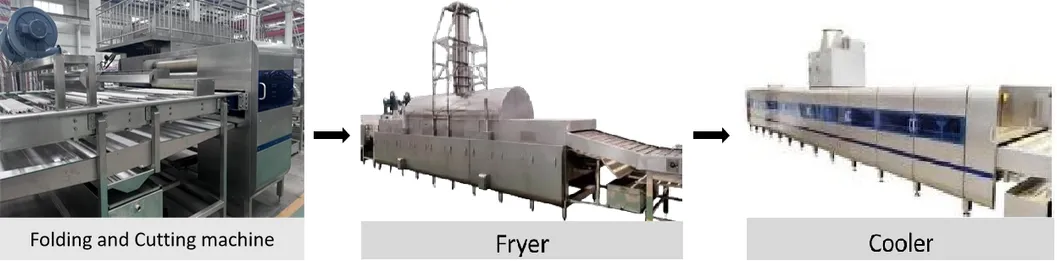

Main machines of one production line:

Dual-axis Mixer

Double shaft/Spiral paddle/Flocculent dough

Dough mixing is the process of mixing and stirring flour and brine mixture in a certain proportion, so that the protein and starch in the flour absorb water and swell to form a flocculent dough. The flour mixer adopts a double-shaft structure, and the stirring paddle is in a spiral shape on the shaft. The two shafts rotate in opposite directions, so that the flour can fully absorb water and be uniform.

The Single Roller Machine

Individual power Automatic Photoelectric

The new type roller machine adopts an integral structure, It consists of a feeding hopper, a feeding shaft, multiple groups of pressing rollers and the slitter device. The feeding shaft adopts four axises to make the feeding process continuous and uniform. Each roller adopts individual power, frequency control of motor speed, and the photoelectric tracking technology is used to automatically adjust the speed of the dough sheet conveying. With the electric and automatic control, do not require manual labor. The end consists of a slitter and a forming device that makes the noodles become wave-shape.

Water-sealed 3-layer Steamer

Water-sealed automatic photoelectric

The steam box adopts a water-sealing structure to ensure the steam does not leak, which solves the problem that the traditional multi-layer steamer must be sealed with rubber strips. The internal steam pipes are carefully arranged to ensure the gelatinization effect and save a lot of steam. The upper cover can be lifted and lowered as a whole, which is convenient for cleaning. And the mesh belt is made of stainless steel, which is safe and hygienic.

Square Noodle Cutting Machine

Quantitatively axial fan total output

This machine is used to cut and fold the steamed corrugated noodles quantitatively, and then transport the noodle pieces to the noodle box of the fryer. Before cutting, the noodles are cooled by axial fan and sprayed by spraying device. Noodles become loose and easy to shape. It can determine the size of noodle cake and its speed can change the total output.

Fryer

High temperature Crispy Uniform

This machine is used to fry the cut and formed noodle blocks at high temperature, so that they can be quickly dehydrated and dried to form crispy instant noodle blocks. The fryer is divided into two areas, front and back, the temperature is self-controlled, and the color of the fried noodle blocks are uniform.

Key words:

Fried Instant noodle production line

Layout

Please leave us a message

Feel free to leave your contact information for more information