Long Noodle Machine with Capacity 1000kg/H

Classification:

Product Introduction

After-sales Service: 1 Year

Warranty: 1 Year

Product Details

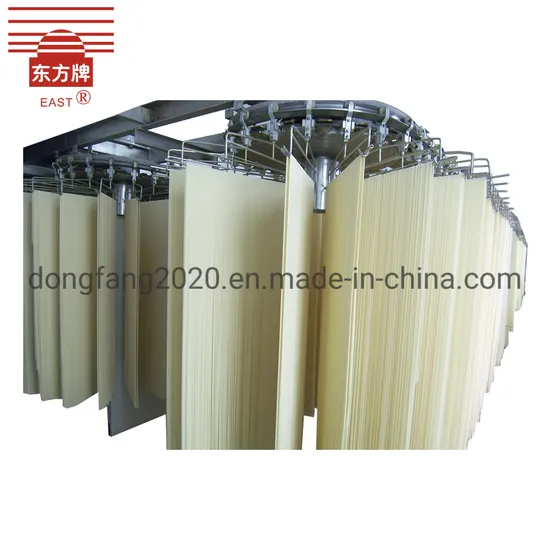

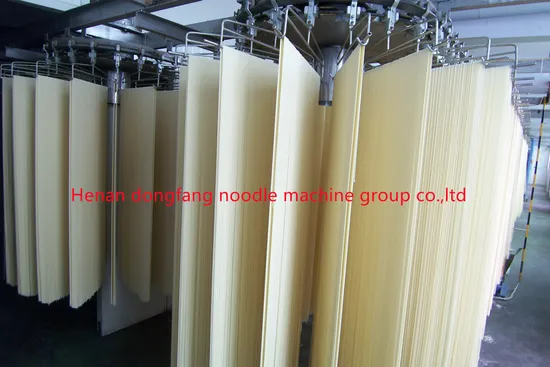

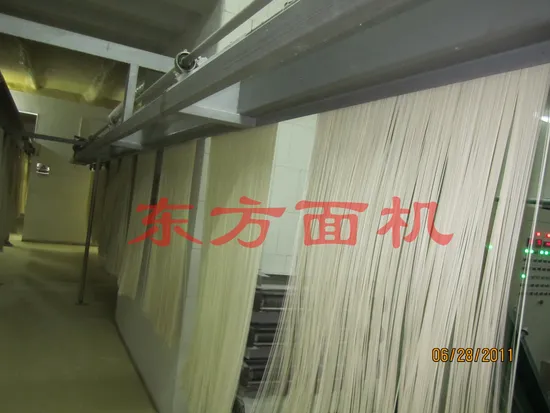

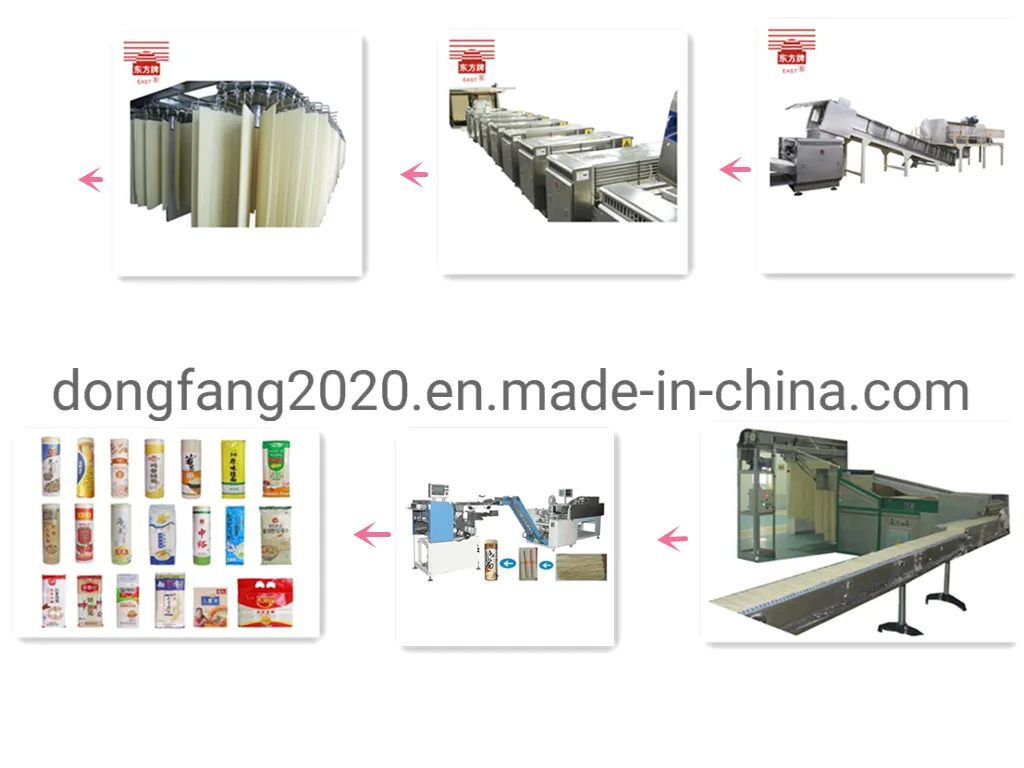

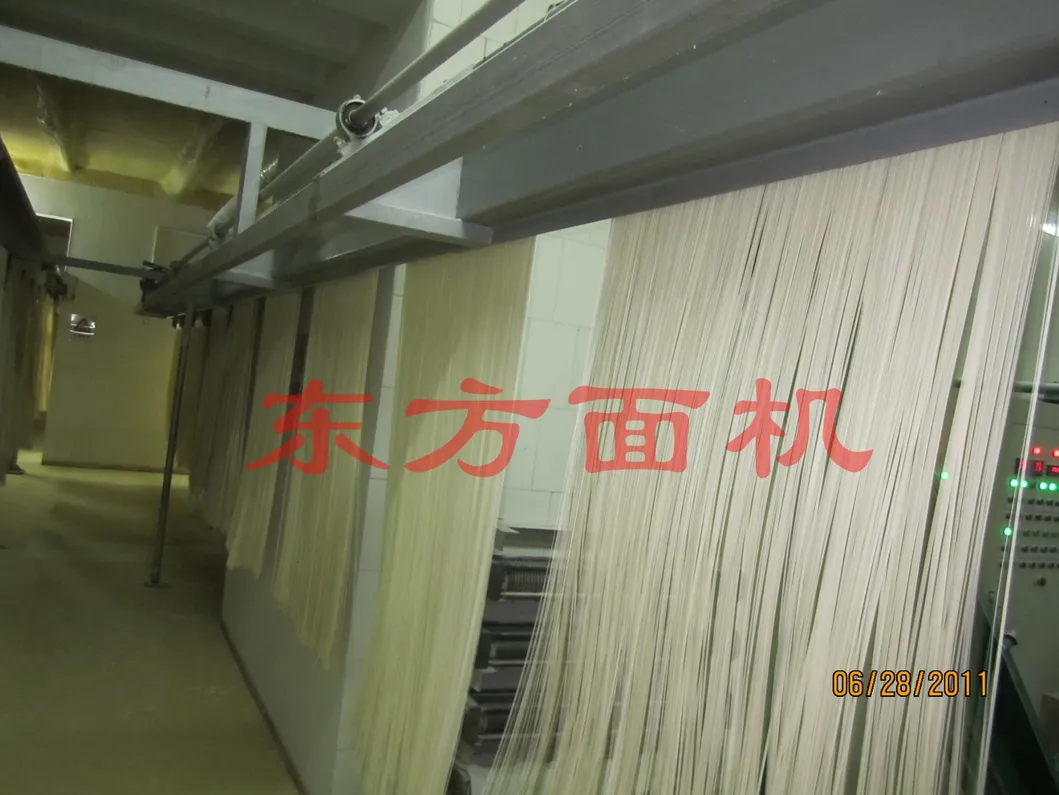

STRUCTURE AND PRINCIPLE OF TYPE 1000 STICK NOODLE PRODUCTION LINE

The stick noodle production line is composed of brine mixer, brine measuring device, dual-axis dough mixer (frequency control), aging machine, single roller, new type drying system, automatic down-shelf, automatic single blade cutter and other equipment, which are connected and assembled into an automatic production line

Technical advantages

This product has the technical advantages of low building cost, high thermal efficiency, low energy consumption, stable equipment operation, good drying process control, good product quality and so on. It is of great significance to improve the production technology level of Chinese stick noodle, and it is the technical guarantee for traditional stick noodle production enterprises to improve the product quality, production technology level and achieve economic benefits. At the same time, the project is in line with the relevant policies of the state and local governments to develop agricultural products processing, improve the added value of wheat, and industrialize the main food, so it has a broad application prospect.

1. Main technical parameters:

(1) Output:10T-20T/24h

(2) Roller pairs :8 pairs

(3) Total power :around 101 kw

(4) Stick noodles specification:width 1mm~6mm,thickness 0.8mm~1mm,ф1mm~1.5mm

(5) Stick noodle length :200,240mm adjustable

(6) Drying time:4h~4.5h

2.Product list for you to choose from

| Model | Power | Steam consumption | Workshop dimension(m) | Workers | Workshop dimension(m) | Workers |

| 350 | 47KW | 400KG/H | 66*9*4.5(+3.5) | 5 | 40*7*4(+3.5) | 5 |

| 450 | 58 KW | 500 KG/H | 70*11*4.5(+3.5) | 6 | 50*8*4(+3.5) | 6 |

| 550 | 63 KW | 750 KG/H | 75*12*4.5(+3.5) | 8 | 65*9*4(+3.5) | 7 |

| 650 | 78 KW | 850 KG/H | 90*14*4.5(+3.5) | 8 | 65*10*4(+3.5) | 7 |

| 765 | 90 KW | 1000 KG/H | 115*16*4.5(+3.5) | 10 | 70*10*4.5(+3.5) | 8 |

| 850 | 98 KW | 1200 KG/H | 70*11*4.5(+3.5) | 9 | ||

| 1000 | 108 KW | 1400 KG/H | 70*12*4.5(+3.5) | 9 | ||

| 1500 | 300KW | 2000KG/H | 85*12*4.5(+3.5) | 9 | ||

| workers:( not including packaging workers ) | ||||||

3. Product details

dough mixer

The highly automatic continuous dough mixer can save labor and construction cost by combining flour feeding, water supplying, mixing and dough feeding together. The dough absorbs water more fully and evenly.

Rolling Machine

Rolling Machine adopt different diameter roller rolling, is advantageous to the gluten forming;Ripple roller rolling,make the dough sheet draging in multi directions. improve the dough sheet quality. each roller adopt independent driving. Effectively guarantee the reliability of the transmission, and the structure is simplified, easy to maintenance.

Automatic drying room 1

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying;Through frequncy control adjusting the humidity and tempreture of each drying section, convenient and reliable; Clever drying room design can make the both end humid air flow toward the middle, , reduce the energy consumption 20-30%.

Automatic drying room 2

The Dongfang newly designed tunnel with adoption of special chain system and longitudinal conveying system, keeps moisture and temperature changing continuously with stable noodle conveying;Through frequncy control adjusting the humidity and tempreture of each drying section, convenient and reliable; Clever drying room design can make the both end humid air flow toward the middle, , reduce the energy consumption 20-30%.

Noodle cutter

Noodle cutter highly automatic,With the technology of speed adjusting system, noodle length can be controlled as desired.

Key words:

Stick noodle production line

Layout

Please leave us a message

Feel free to leave your contact information for more information