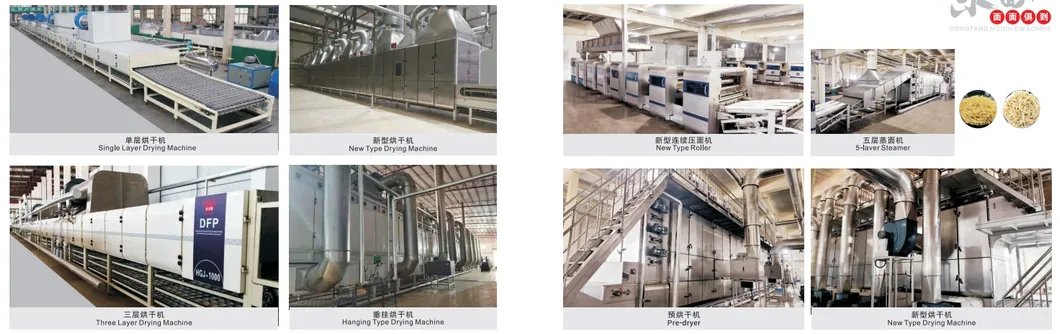

Efficient Energy-Saving

The use of advanced hot air circulation technology and thermal energy recovery systems enables the rapid drying of wet noodles to the desired moisture content. Additionally, these technologies significantly reduce energy consumption, thereby lowering production costs.

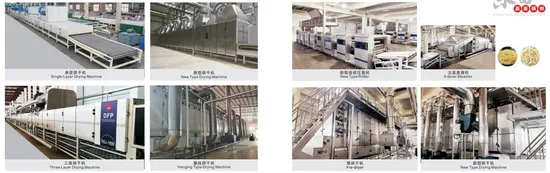

Quality Assurance

The production line is equipped with temperature and humidity sensors inside, which can monitor and control the drying environment in real-time to ensure that the wet noodles do not deform, discolor, or develop cracks during the drying process.