Non Fried Round Instant Noodle Making Machinery

Classification:

Product Introduction

After-sales Service: 1 Year

Warranty: 10 Years

Product Details

Product Description

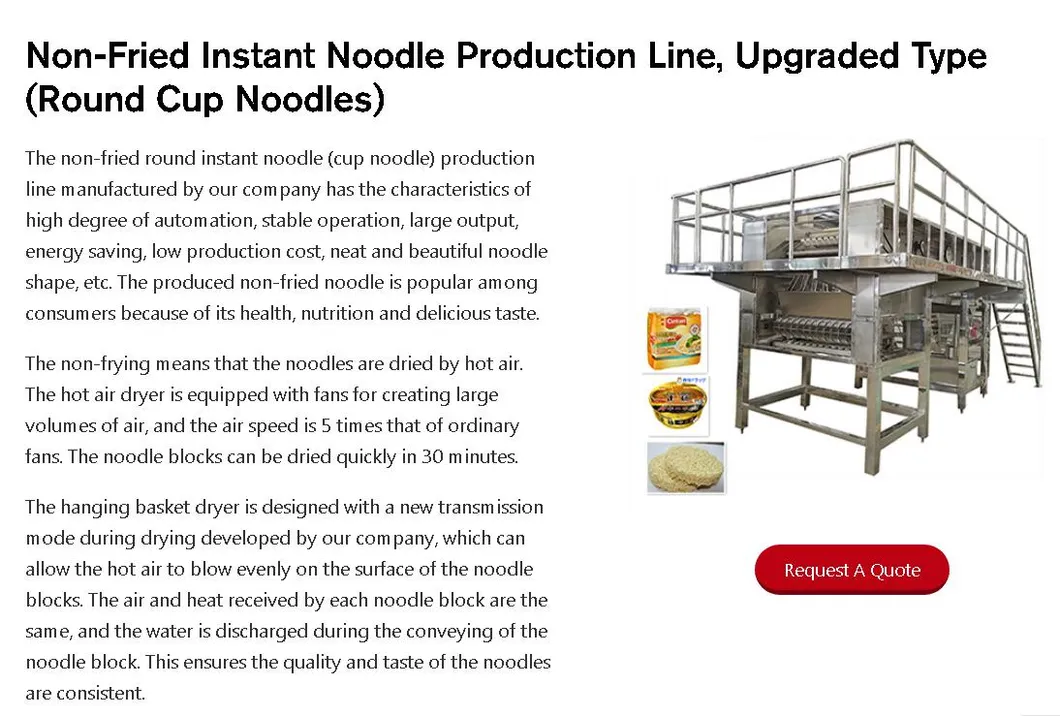

Non-fried round instant noodle production line

The production technology of non-fried instant noodles is basically the same as that of fried instant noodles.The main difference is that the noodle cake is made by micro expansion technology and hot air drying technology.The moisture content of non-fried instant noodles is less than 10%, which is more.

Non-fried instant noodles have the following characteristics:

1.The drying time is long and the fine organization of noodles.

2.The oil content is less, so it is close to the raw flour and has a light taste.

The drying speed is fast, and there is no difference between the produced non-fried noodle cake and fried noodle cake except oil-free;Compared with the noodle cake produced by other drying equipment, the same kind of noodle cake has large weight, large volume and full appearance.

Main production models:

WFP-6(60000/8h),

WFP-8(80000/8h),

WFP-10(100000/8h),

WFP-12(120000/8h),

WFP-16(160000/8h).

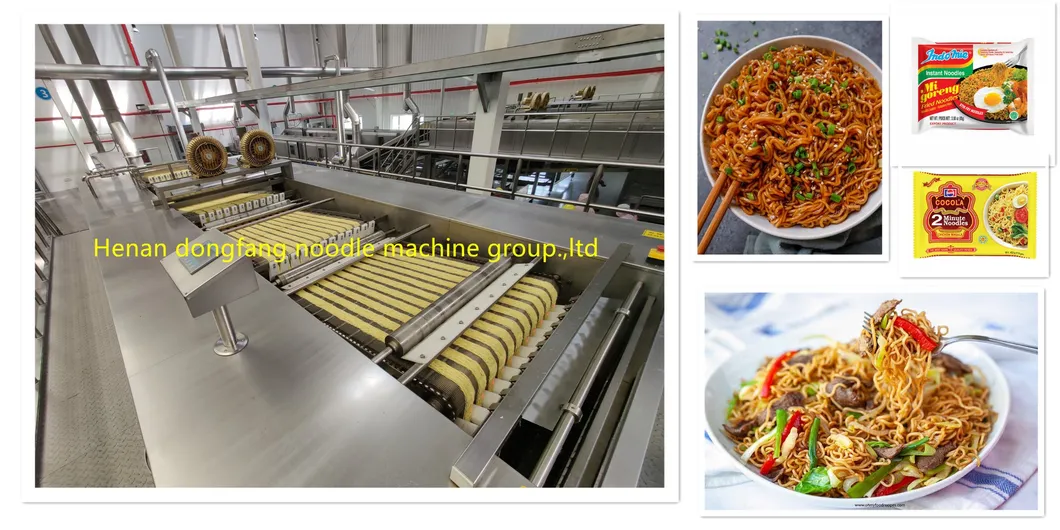

This series of products have the characteristics of new technology, reasonable technology, stable operation and convenient maintenance.And be responsible for installation, commissioning equipment and training operators.

Introduction to main equipment

continuous mixer

With high level of automation, the continuous mixer can supply flour and water, knead dough and feed at same time. The dough and the flour is well blended and in slight color variation. With simple building structure and reliable operation, reduces the investment cost largely.)

new type Roller machine

The 1000 new type Roller machine adopts a brand-new appearance design, which is beautiful and novel, giving people a completely new feeling. Adopting four-axis feeding, smooth feeding, ensuring the integrity of the noodle sheet, and excellent sheet forming effect

Waving

After the noodle strip is cutted by the slitter, it enters the pattern forming device, and after it comes out, it forms a wave

Multi-layer Steamer

Water-sealed multi-layer noodle steamer is a new product developed by our company. It has a smooth appearance and is water-tight and air-tight, which solves the problem that the traditional multi-layer steamer must be sealed with rubber strips

Round noodle cutting machine

The steamed noodles are cut to a fixed length after being sprayed by waterfall and with three times stretching, and then fall into the noodle box through the sliding floating bucket. The noodles can be stretched for three times to basically straighten the noodles, which provides good conditions for the automatic shaping machine in the subsequent process.

Dryer

Dryer shown in the picture is the latest type of recent years, it improves the wind speed and temperature, also can ensure relative stability of noodle cakes, without shifting. The maximum temperature can reach 150 ºC, the scientific hot air circulation system makes full use of the heating energy, improves the baking effect. Moreover, two minutes of drying time will achieve the requirements of production process.

Key words:

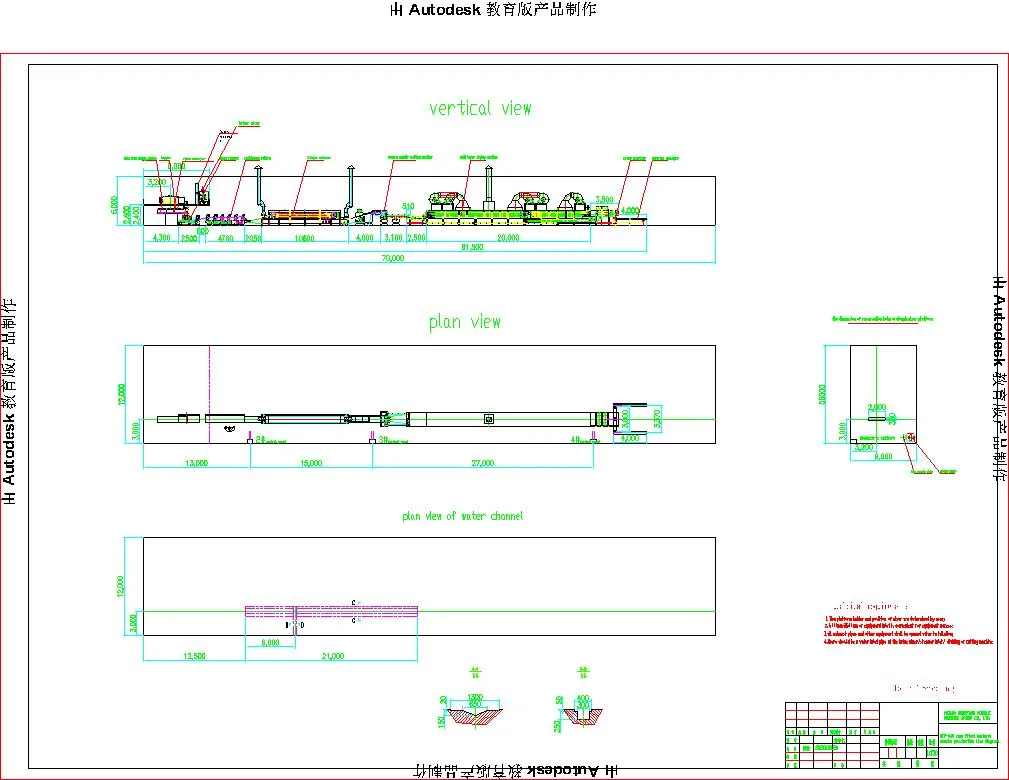

Layout

Please leave us a message

Feel free to leave your contact information for more information