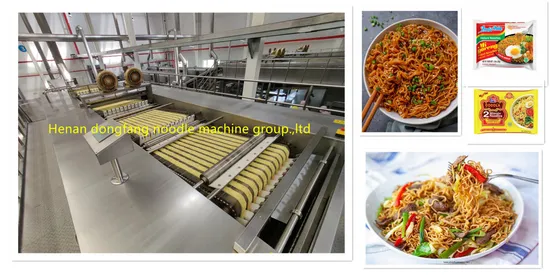

Round Fried Instant Noodel Production Line with New Technology and Full Automation

Classification:

Product Introduction

After-sales Service: 10 Years

Warranty: 1 Year

Product Details

Brief Introduction:

The fried instant noodle equipment production line is an integrated, fully automatic instant noodle production line that encompasses dough mixing, aging, rolling, cutting, steaming, frying, and cooling processes. It features a modular design, achieving full-process automation from raw materials to finished products, making it an ideal choice for modern instant noodle manufacturing companies to increase production capacity and ensure product quality.

Product Features:

1. High Automation and Easy Operation

- PLC intelligent control system for precise automated production.

- Touchscreen interface for simple and user-friendly operation, reducing the difficulty of operation.

2. High Production Capacity

- A production capacity of up to 160,000 packs in 8 hours, meeting the demands of large-scale production.

- A quick mold change system to flexibly adapt to market changes.

3. Precise Process Control

- Vacuum mixing, multi-stage rolling, and precise cutting to ensure noodle quality.

- Intelligent temperature control system to guarantee the effect of steaming and frying.

Different product model:

| Capacity | Power | Steam consumption | Workshop for single layer steamer dimension(m) | Workshop for three layer steamer dimension(m) | Workers |

| 60000pcs/8H | 56 KW | 1200-1400KG/H | 75*5*4 | 60*5*4 | 4 |

| 80000pcs/8H | 68 KW | 1300-1500KG/H | 80*6*4 | 65**4 | 4 |

| 100000pcs/8H | 80 KW | 1400-1600KG/H | 90*6*4 | 70*6*4 | 4 |

| 120000pcs/8H | 83 KW | 1800-2200KG/H | 100*6*4 | 75*6*4 | 5 |

| 160000pcs/8H | 106 KW | 2000-2200KG/H | 100*7*4.5 | 80*7*4.5 | 5 |

| 200000pcs/8H | 114 KW | 2400-2600KG/H | 110*8*4.5 | 80*8*4.5 | 5 |

| workers:( not including packaging workers ) | |||||

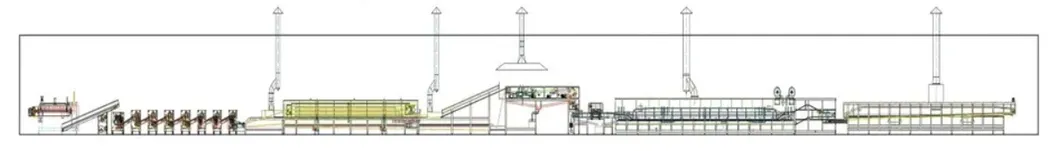

Production layout:

Main products :

Flour mixer

Including:(1)dual-axis,Bearing Nan'an, (2)self-made steering box,(3)helical gear reducer,(4)cleaning roller discharge,(5)manual and pneumatic opening and closing. (air pump not included)

Material: (1)304Stainless steel: tank body,shaft and paddles, guard cover, upper cover. (2) Carbon steel: base (cover 304stainless steel), transmission parts and self-made box.

Ripen conveyor

Including:(1)spiral crushing (2) conveyor belt (3) main and driven rollers (4) belt rollers (5) self-vertical anti-side leakage seal.

Material: (1) 304 stainless steel: crushing shaft teeth, side plates, upper cover, safe guard. (2) 201 stainless steel: down-shelve legs, upper box bracket, supporting roller. (3) Carbon steel: transmission parts, driving roller (rubbed), driven roller (nickel plated).(4) Polymer: sealing plates on both sides.

Continuous roller

Including: the last two bear is Japanese NSK,up noodle slice by hand,,hand-wheel with meters adjust the thickness of noodle slice, photoelectric tracking compensate speed, strong magnet one group,2 square slitters, waving device two groups,noodle comb 4 pairs.

Material:304 stainless steel :guard cover,waving device,sealing plate ;Alloy roller,Nylon cover plate;Copper scratch knife ;Carbon steel :frame,driven parts,machine base(Outsourcing of 304 stainless steel), wall panel (galvanized), flange, noodle knife.

3-layer Steamer

Including: stress reducing valve*1,Internal and external mesh belt, chains, track, and exhaust chimney(8×2)m, including mesh brushing,steam pipe valve.

Material: 316 Stainless steel inner mesh, gas ejector pipe; Carbon steel: lifting device, reducer, valve, external pipeline.Nylon: nylon roller, brush roller;304 stainless steel others.

Round noodle cutting machine

Including: three times stretch,spray pipe,water receive pan,fan 1set ,axial flow fan 2sets

Material: 304 stainless steel:frame,cover board,chain mesh,chains,rail,axis, chain wheels.Carbon steel: driven parts, hopper used particle board

Blowing and shaping machine

Including: pneumatic turning ,with stop blowing detection

Material:304stainless steel:frame,blower;Carbon steel: driven parts

Fryer

Including: noodle box and noodle box lid each 1set, 4 oil inlet,automatic oil replenishment, automatic temperature control,automatic up and down vibration box device,floating oil scraping device

Material:304stainless steel: cover board, guard cover, chimney, noodle box and cap,oil scraping plate;Carbon steel:body, frames, chain, trails, pipes, valve, axis,chain wheel.

Arranging machine

Including: soft round rope to undertake and transport,pneumatic arranging, noodle pieces catching plate,oil receiving pan

Material:304stainless steel:noodle pieces catching plate,oil receiving pan,frame,stop rod, shaft;Carbon steel:air cylinder;Nylon: roller; Edible grade rubber: round rope.

Cooling machine

Including:round hat navigation bar track,push rod,exhaust fan*1,supply fan*2,centralized exhaust air, wind duct 8 meters.

Material: 304 stainless steel: frame, sealing plate, door, track, air duct;Carbon steel: shaft, sprocket, push rod chain, transmission parts

Detailed specification Other equipments:

Key words:

Layout

Please leave us a message

Feel free to leave your contact information for more information