Round Instant Noodle Production Line with CE and Big Capacity

Classification:

Product Introduction

Customized: Customized

Certification: CE, ISO9001

Product Details

Brief Introduction:

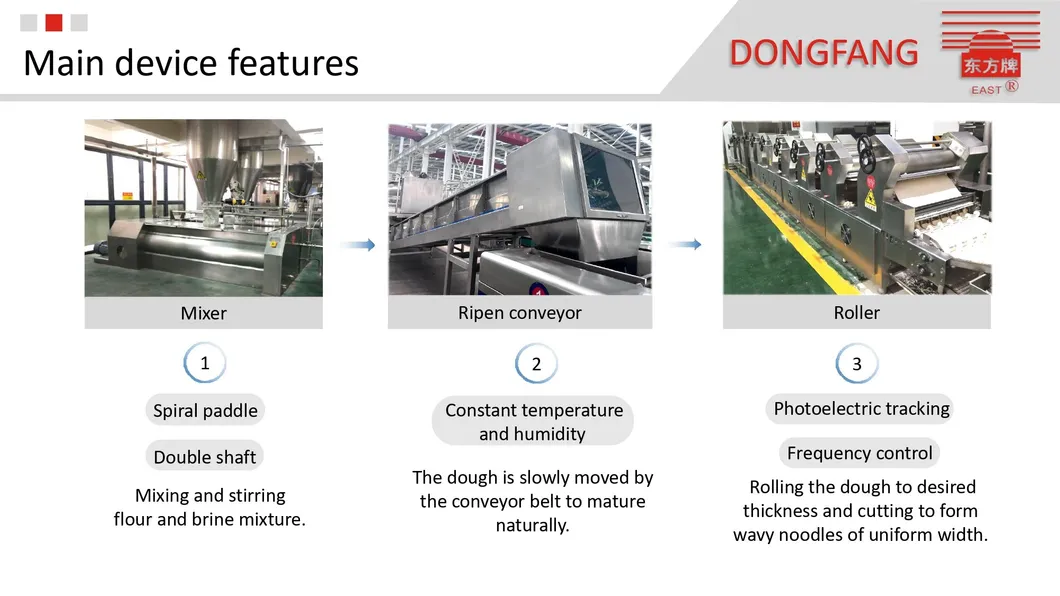

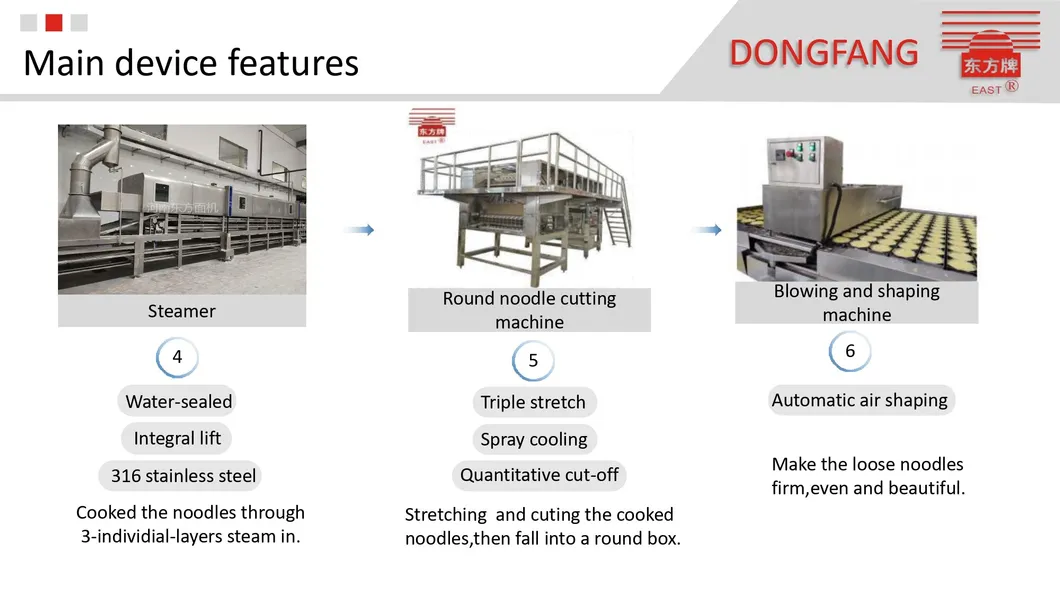

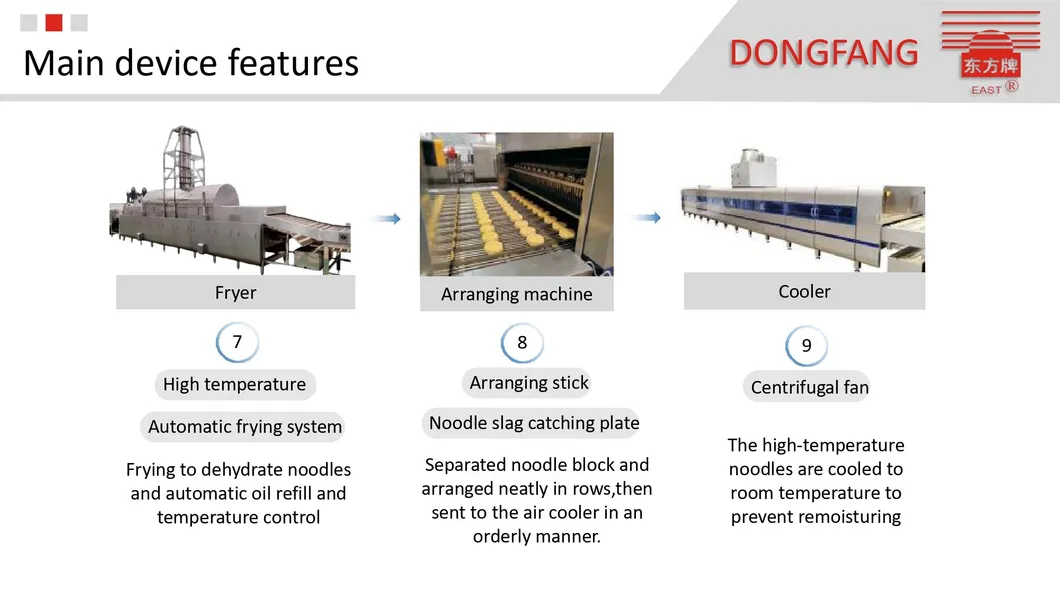

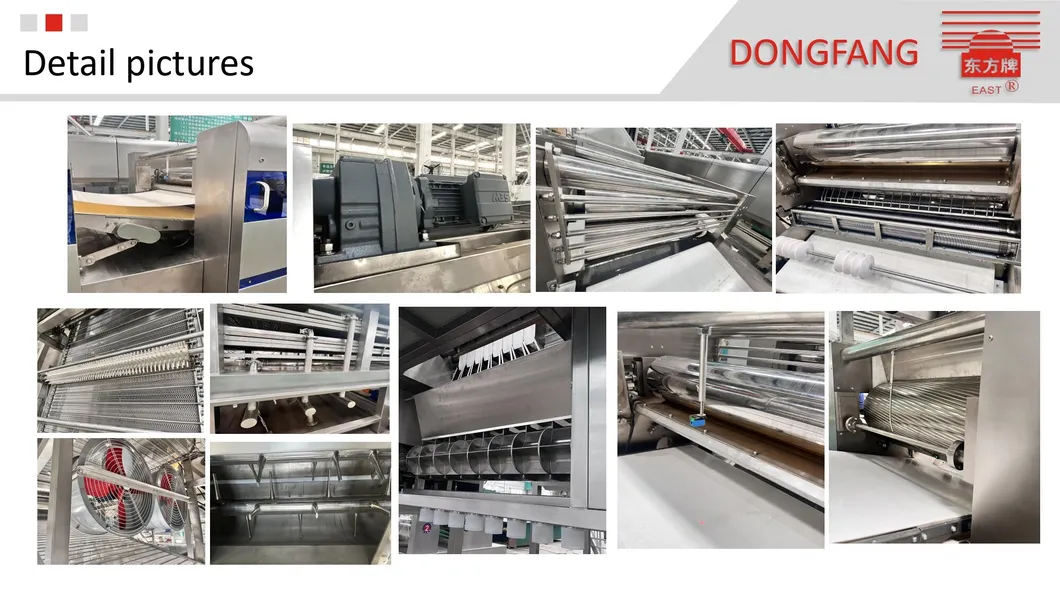

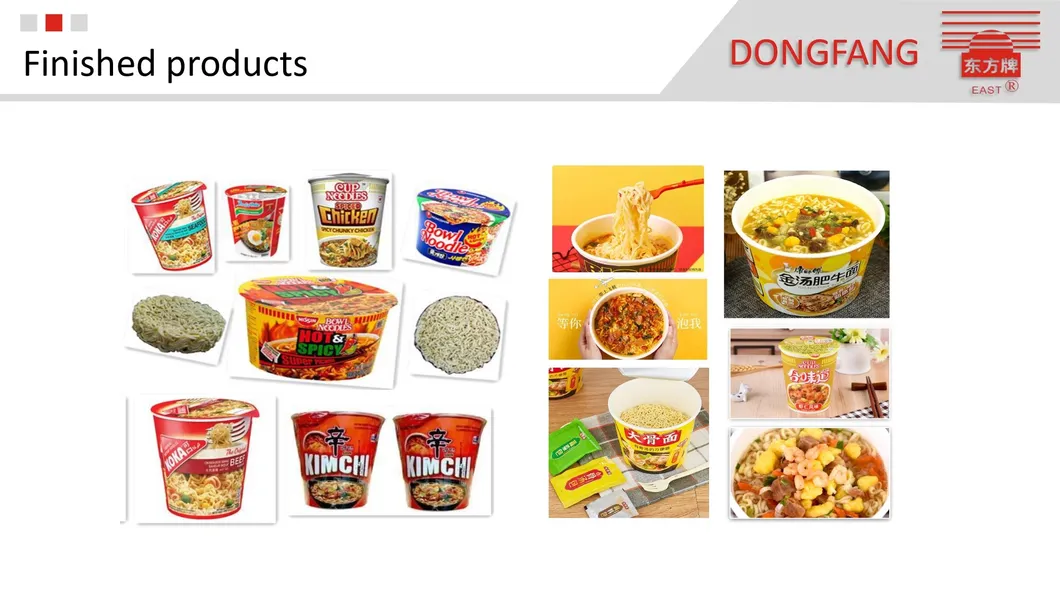

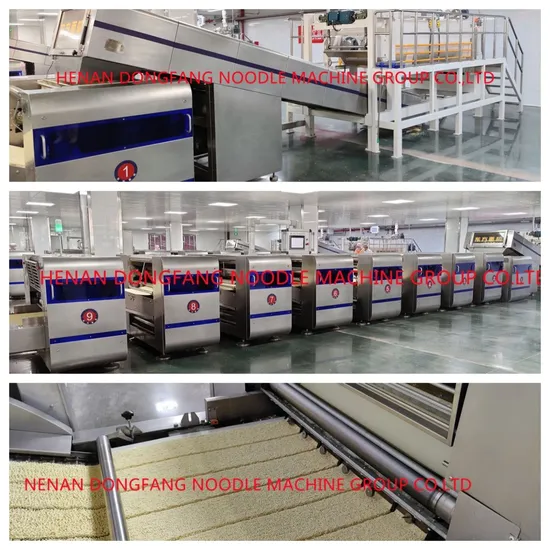

The fried instant noodle equipment production line is an integrated, fully automatic instant noodle production line that encompasses dough mixing, aging, rolling, cutting, steaming, frying, and cooling processes. It features a modular design, achieving full-process automation from raw materials to finished products, making it an ideal choice for modern instant noodle manufacturing companies to increase production capacity and ensure product quality.

Product Features:

1. High Automation and Easy Operation

- PLC intelligent control system for precise automated production.

- Touchscreen interface for simple and user-friendly operation, reducing the difficulty of operation.

2. High Production Capacity

- A production capacity of up to 160,000 packs in 8 hours, meeting the demands of large-scale production.

- A quick mold change system to flexibly adapt to market changes.

3. Precise Process Control

- Vacuum mixing, multi-stage rolling, and precise cutting to ensure noodle quality.

- Intelligent temperature control system to guarantee the effect of steaming and frying.

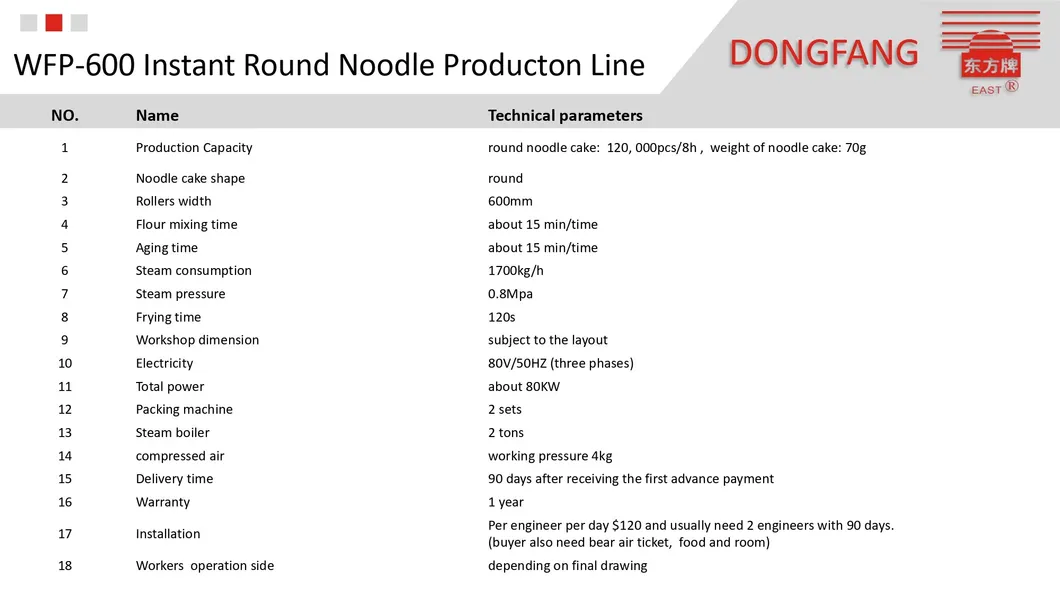

Main Parameter:

| Model | Production Capacity | Installation Capacity | Steam Consumption | Workshop Requirements L*W*H(meter) |

| 1000 type | 420 pcs/min | 180KW | 2800kg/h | 130*8*6 |

| 900 type | 360 pcs/min | 180KW | 2400kg/h | 130*8*6 |

| 800 type | 330 pcs/min | 150KW | 2200kg/h | 120*6*6 |

| 700 type | 290 pcs/min | 140KW | 1900kg/h | 120*6*6 |

| 600 type | 250 pcs/min | 120KW | 1700kg/h | 110*6*6 |

| 500 type | 208 pcs/min | 90KW | 1400kg/h | 110*6*6 |

Detailed Introduction:

Key words:

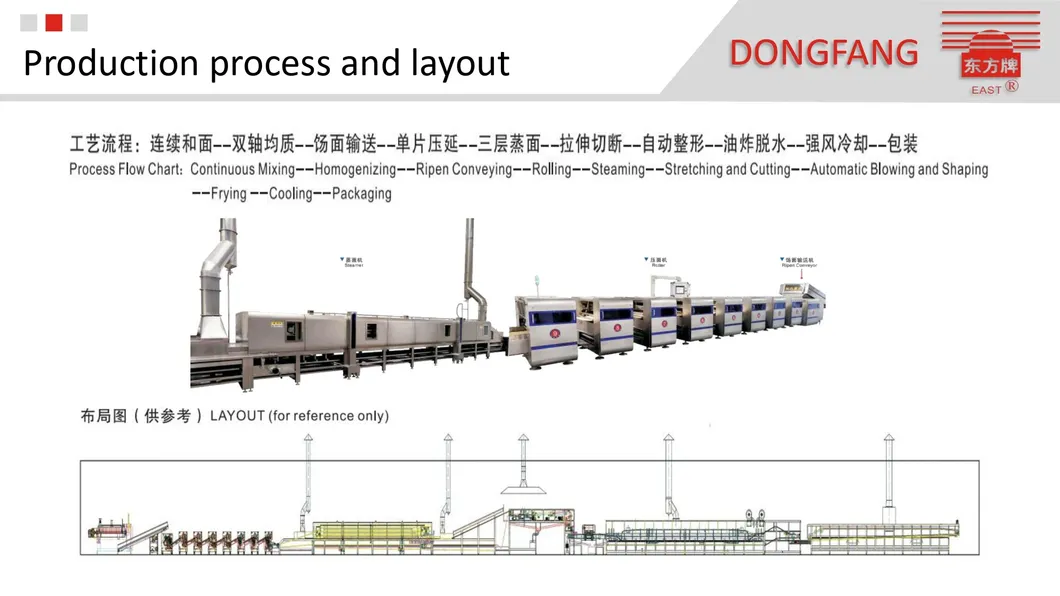

Layout

Please leave us a message

Feel free to leave your contact information for more information

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Message

Feel free to leave your contact information for more information

Mobile Web

Tel :+86-13014581810

Tel :+86-15515875877

Fax :+86-371-67861319

E-mail : eastnoodleline@gmail.com

Address :18# DONGFANG ROAD, MAZHAI INDUSTRIAL PARK, ZHENGZHOU, CHINA.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home